Successful revamping at the Drusenheim Wastewater Treatment Plant

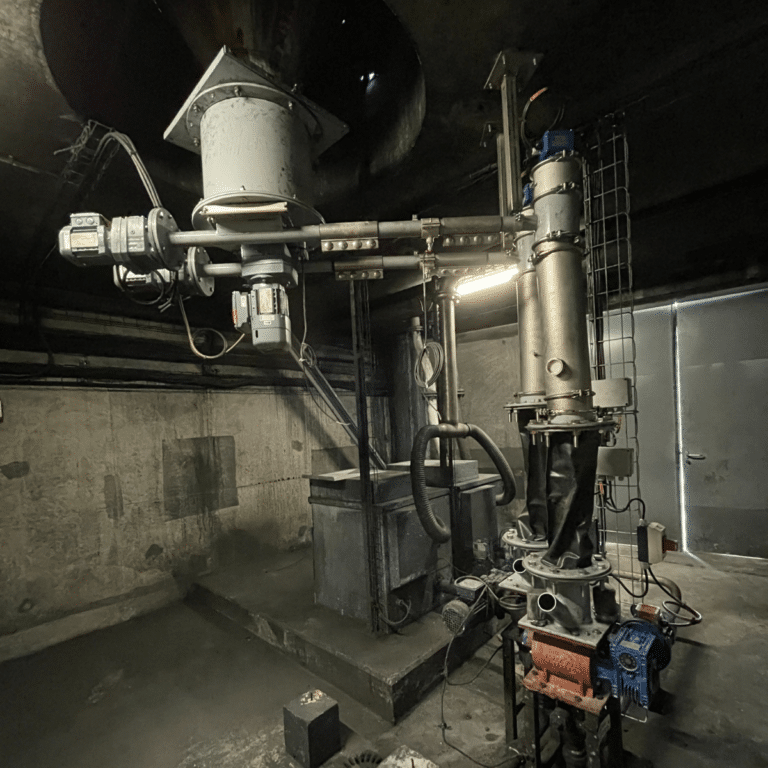

This turnkey project, carried out for our client Sogea and operated by the Alsace-Moselle Water and Sanitation Authority (SDEA), involved replacing an outdated installation with modern, high-performance equipment.