Feeding and conveying ashes as part of the AMPHORE project in Bottrop, Germany: Successful commissioning

The AMPHORE project marks a significant milestone in sustainable recycling in Europe. Conceived as a demonstration plant, this ambitious project aims to meet Europe’s growing fertilizer needs by recycling phosphorus, a resource with limited reserves, from sewage sludge. Thanks to the plant supplied by Sodimate, sewage sludge ash is extracted and transported efficiently and precisely, contributing to large-scale phosphorus recycling.

Sodimate: a technology partner at the heart of the process

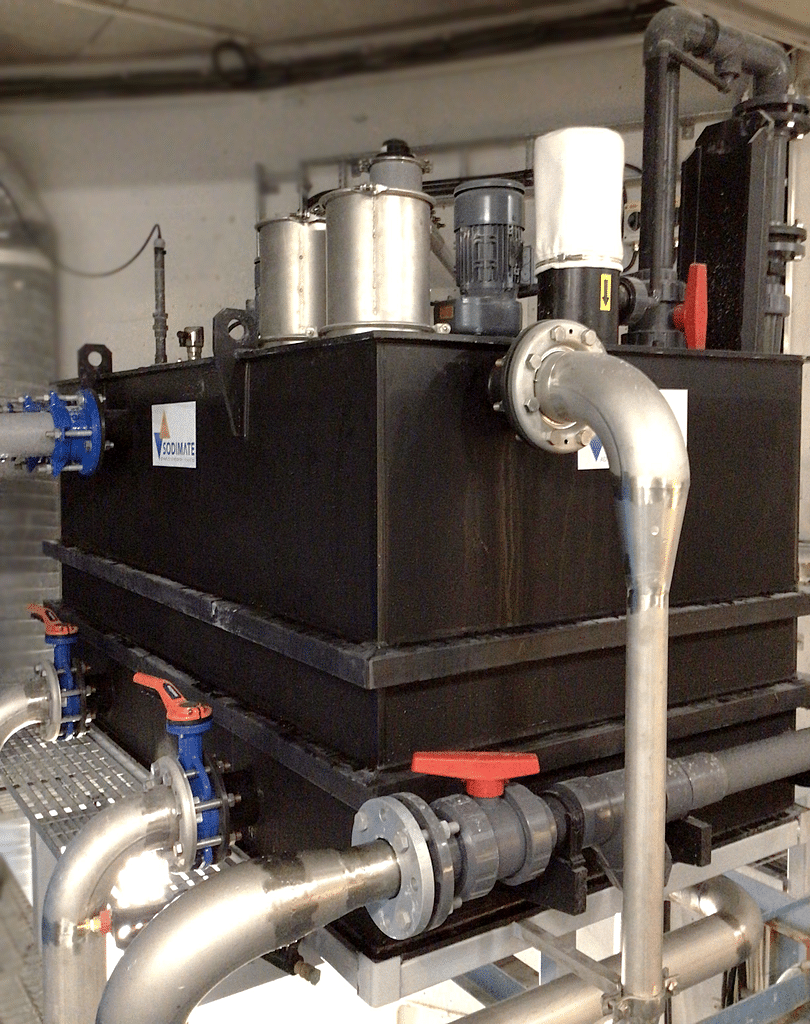

As part of this turnkey project, Sodimate installed equipment for dosing, extracting, weighing and transporting sewage sludge ash.

Here are the main components of this innovative plant:

- Three extraction and dosing systems: Mechanical bin activators installed under silo to guarantee homogeneous extraction and dosing.

- An intermediate hopper : Designed to serve as an intermediate weighing tank, enabling rigorous monitoring of the quantity transferred: loss in weight feeder.

- Several screw conveyors: Integrated to ensure fluid, continuous conveying at every stage of the process.

- An injector : for transporting sewage sludge ashes into an acid-filled on-site reactor.

A complete service for optimum results

The turnkey project included all key stages: from engineering to manufacturing, delivery, installation and commissioning. This integrated approach guarantees the quality, performance and durability of the equipment installed, enabling rapid commissioning and process optimization from the very first phases of operation.

An operational success for the environment

Since its commissioning a few months ago, the plant has been operating successfully, demonstrating the effectiveness of Sodimate’s technical solutions and their essential contribution to environmental sustainability. Our team is proud to play an active part in the transition to more responsible management of natural resources.