As part of the compliance with new environmental standards imposed by BREF 2023, an Energy Recovery Facility located in the Marne region has undertaken a complete modernization of its installations. Sodimate was called upon to optimize the storage and dosing system for Sorbacal micro, an essential reagent for the treatment of industrial emissions.

A comprehensive solution for the reduction of pollutant emissions

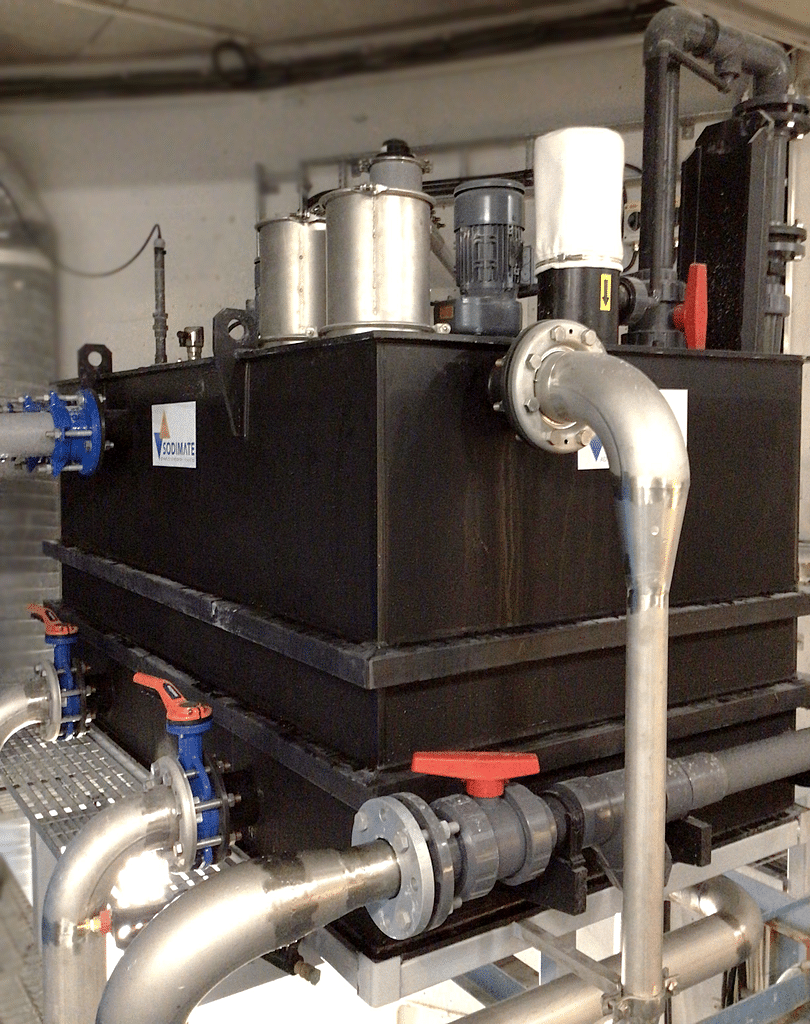

To meet the strict requirements for reducing emissions of mercury and dioxins, Sodimate provided a set of technical solutions tailored to the facility’s specific needs. These solutions include:

- A large-capacity silo designed to ensure secure and optimized storage of Sorbacal micro.

- A discharging and dosing system to guarantee a precise and continuous product flow.

- Two pneumatic transfer lines for the efficient and continuous distribution of the reagent to the facility’s two municipal waste incineration lines.

Safety and reliability: A top priority

In addition to the installation of new equipment, the two existing big-bag stations have been retained as backup solutions. This redundancy enhances the operational safety of the facility, ensuring uninterrupted service in case of any primary system failure.

A strong commitment to environmental protection and regulatory compliance

This modernization is fully aligned with Sodimate’s commitment to environmental protection and adherence to the highest industrial standards. By adapting its equipment to meet BREF 2023 requirements, Sodimate actively contributes to the reduction of pollutant emissions— a crucial challenge for the future of waste treatment facilities in France and across Europe.

Sodimate’s involvement in this project demonstrates its ability to deliver tailor-made solutions that meet industrial constraints while respecting current environmental regulations.