Veolia operates the Dieppe wastewater treatment plant, located in Rouxmesnil-Bouteilles, France. The agglomeration community of the Dieppe region takes all necessary measures to ensure the quality of the effluents discharged into its wastewater system.

The Dieppe wastewater treatment plant is currently the third largest in the region after Le Havre and Rouen. It also collects and purifies domestic wastewater and sludge from neighboring stations. This WWTP is sized to treat the effluents of more than 61,000 resident.

The aim of the treatment is to separate water from undesirable substances through a succession of different devices. The retained pollution is transformed in the form of sludge, which is limed and spread on land, while the rest is not limed and used for composting.

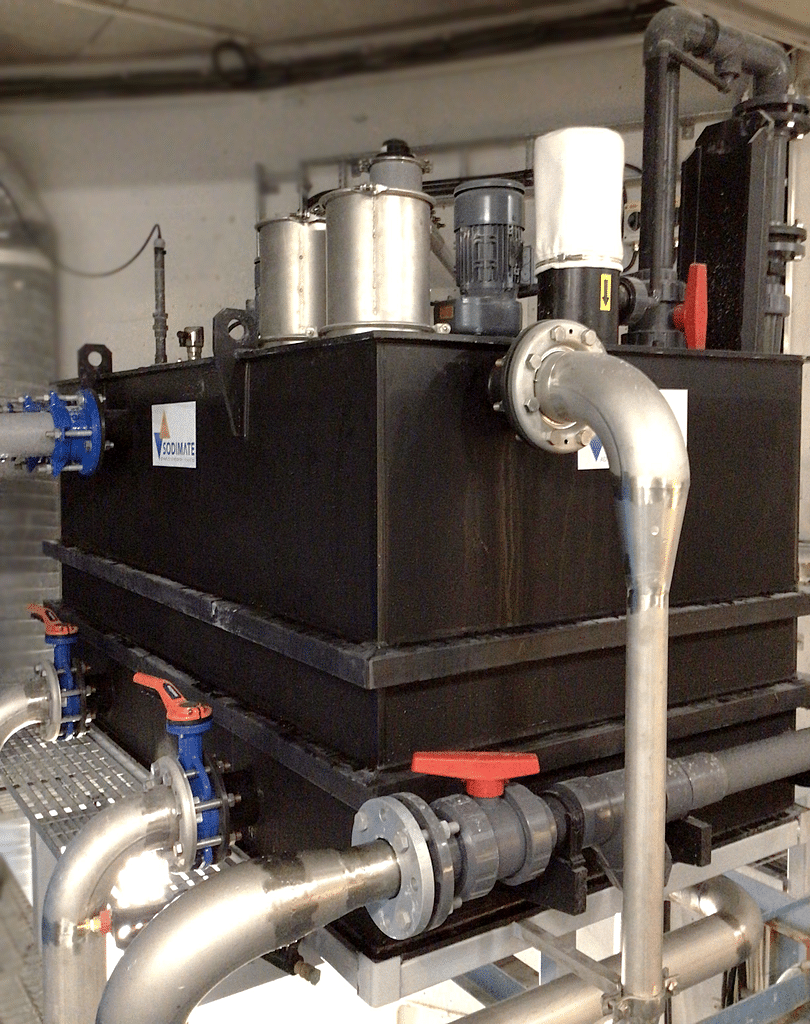

In 2020 Sodimate delivered through the company SOURCES, two preparation unit of emulsion-based polymers.

The first plant is dedicated to sludge dewatering to help achieve a better separation between solid and liquid, a physical-chemical process called flocculation during which the sludge suspended in water agglomerates to form larger particles called flocs.

The second unit is dedicated to the lubrication of a liquid ring installed on the transfer pipe, mounted downstream of a feeding pump allowing the transfer of sludge from the SODIMATE mixer in order to facilitate the transfer without any risk of blockage.

Sodimate has built and tested all the elements of the equipment, accompanied by a complete documentation.

As Mrs. Isabelle Levasseur, maintenance technician, and Mr. François Leroy, head of operations at the STEP, indicate, “the polymer preparation plants have been working very well and without interruption for over a year.”

For this same WWTP, in 2009, Sodimate had previously designed, built and installed for VEOLIA the system of devouting and dosing of quicklime under a storage silo of 80m3, a screw conveyor without core of sludge in recovery of three centrifuges and a double shaft mixer with notched blades. The whole plant is instrumented and equipped with all the necessary inspection and safety devices and has been in operation for over 10 years.