Based on its experience on a neighbouring plant in the field of polymer, SUEZ has selected the company SODIMATE for the design, assembly and commissioning of a complete installation for the preparation of green polymer (bio) from a Big-bag emptying stand, for the Flins sur Seine drinking water plant, one of the largest in Ile-de-France with 80,000 m3 of water treated every day.

The introduction of bio-sourced polymer (starch / potato starch) is a promising environmental solution. This organic reagent is almost 20% decomposed after two years, if the conditioned sludge is used in agriculture. At the Flins sur Seine site, polymer consumption is approximately 1,600 kg/year.

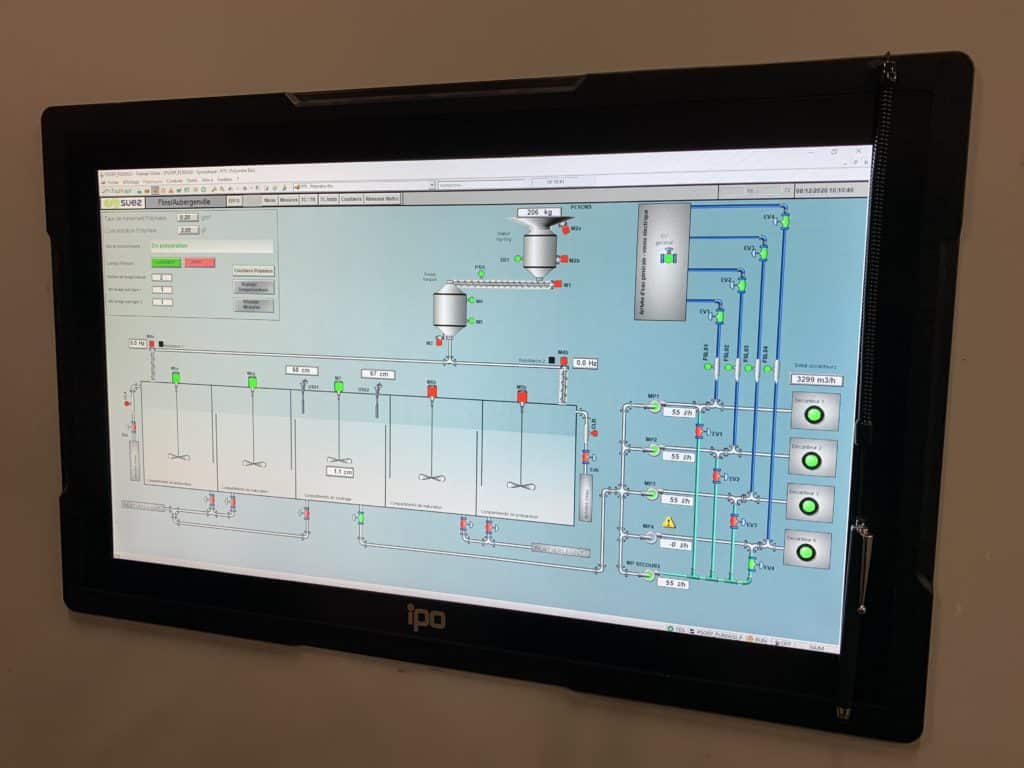

The entire proposed solution includes three sub-assemblies:

– A big-bag emptying station of 1 M3 (about 400 kg) with reduced dimensions, with a lifting beam with automatic unhooking of the hoist and a vibrating table to facilitate the big-bag emptying. In the lower part, a transfer conveyor with a flexible shaftless screw to feed the dosing system.

– A 100 liter buffer hopper, equipped with a mechanical deviator and two volumetric dosing units with a dosing accuracy of +/- 3% and equipped with heating cords to avoid polymer mass setting at the end of the screw due to humidity. The specificity of the hopper is that it can be fed with 25 kg bags by means of a removable lid mounted on a bag holder.

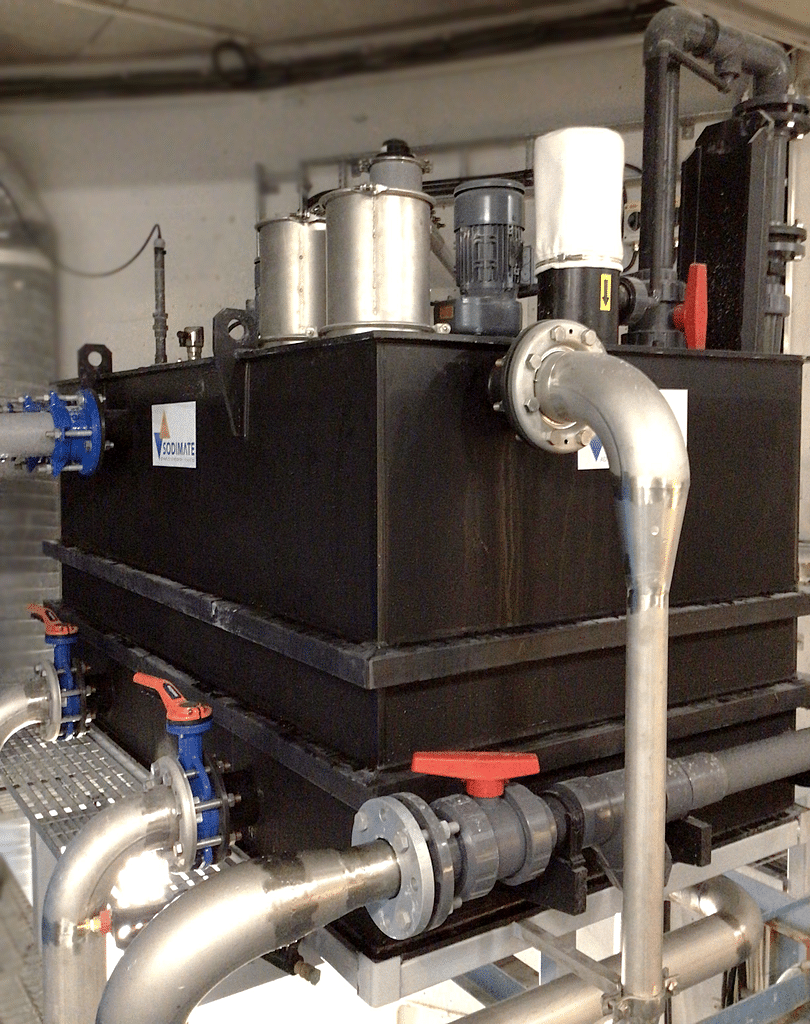

– An innovative polymer preparation tank with two agitated mixing compartments, two agitated maturation compartments and an withdrawal compartment equipped with a radar probe to control the polymer and water injection phases. Each compartment is equipped with a pneumatic emptying valve to automatically empty and clean the desired compartment. This specificity is linked to the fact that the Bio polymer degrades over time (organic matter that enters into fermentation) which requires regular cleaning while limiting the loss of polymer.

To meet the needs of the plant process, the preparation is done at a concentration varying between 1 and 3 g/l of bottling.

Thanks to the precision of the Sodimate volumetric dosing system, the customer did not have to invest in a weight dosing system while maintaining a sufficient flow rate to manage polymer consumption.

Sodimate was able to adapt to the constraints of the site thanks to a tailor-made design.