A weight feeder is an equipment used to feed material volumetrically while at the same time weighing it, and can be used for both granular and powdered solids. There are different types of weight feeders available for different purposes. The following are the main details you should know before choosing Weight Feeder.

What Is the Nature of Your Material?

As mentioned, weight feeders feed material from a hopper into the process. Various material forms can have different flow characteristics, and these are used to select the specific weight feeder you need. Here are some material characteristics:

- Material that’s sensitive to pressure, in which case the material can pack under large head loads, like wax beads.

- Free-flowing material, which flows easily without the need for special equipment or flow aids, like plastic pellets.

- Material that melts at low temperatures, makes it more likely to break down, caramelize, or even melt under excess energy or friction.

- Cohesive material packs together and clumps easily, such as very fine powder or powder with fat content.

- Friable material whose particles break down easily and this requires gentle handling. Examples are flake adhesives and pasta products.

- Adhesive material adheres to all surfaces it comes into contact with like color pigments. This material type is especially difficult to feed.

- Aeratable material behaves like a fluid when it is aerated. It can flood uncontrollably if care is not taken, and examples are flour and glass microspheres.

- Hygroscopic material picks up moisture from the air and can therefore clump easily. Examples of such materials are salt and cellulose fibers, which can harden into a hard clump if left exposed for a night or longer.

- Fibrous material, like biomass fiber and wood flour, has long particles that can interlock and therefore flow slower.

To decide which weight feeder to get, you need to know what kind of material you need to use it for.

E.g., A gravimetric feeder is used for powders such as activated carbon powder, hydrated lime, clay, and polymer that need steady & continuous feeding, high powder metering accuracy, and instantaneous flow rate.

What Do You Need Your Feeder for – Batching or Blending?

One of the major factors in choosing the right weight feeder is based on the type of batching or blending process you need. Here are the details.

Batching equipment generally involves putting a specified amount of material into a process or a mixture or filling containers. In this case, it’s crucial to be able to start and stop the flow depending on a predetermined batch amount.

Dynamic weighing or continuous weighing is used to calculate the flow of an uninterrupted stream of material.

With these details, you can decide on the most important features you want it to have and thus decide which feeder you will get.

Which type of Feeder Do You Need – Volumetric or Gravimetric?

The two most readily available weight feeder types are volumetric feeders and gravimetric feeders.

A volumetric feeder is simple and includes screw conveyors, belts, and rotary valves, among others. Typically they work at a specific speed, set by the feeder they’re connected to; thus, not much calibration. Also, calibration is challenging if any change is required. Though they are easy to maintain and are less expensive, they’re also less accurate as variables like product temperature, size, density, and even moisture content in the air can affect the amount of material they process.

A gravimetric feeder, on the other hand, measures the mass of the product traveling through it, which makes it control the flow rate better. It is the preferred option when accuracy is paramount. One of the best advantages of a gravimetric feeder is automatic calibration which makes scaling possible at any required time. The gravimetric feeder is a collective term used to refer to a few different types of feeders, but the most common and popular is the loss-in-weight feeders.

The main advantage of loss-in-weight feeders is they can simultaneously measure large weights and small incremental changes in the weight.

Loss in weight systems is perfect for applications that need high powder metering accuracy, instantaneous flow rate, and accurate control of consumption. There’s no better option when you require simple, reliable, and precise operations to suit high industrial standards. You can also integrate it after big bag emptying units.

A gravimetric feeder and a volumetric feeder may appear to be similar at first look. However, the difference could be night and day, depending on your requirements and operations. Going for volumetric systems just because their initial cost is low is not the right way of choosing a weight feeder. A volumetric feeder may be cheap to purchase in the short run, but over time you will save more money with a gravimetric feeder.

The gravimetric feeder, especially the loss-in-weight feeder, is 10X faster, simple, reliable, and more accurate in operations.

The Feeder That’s Right for You

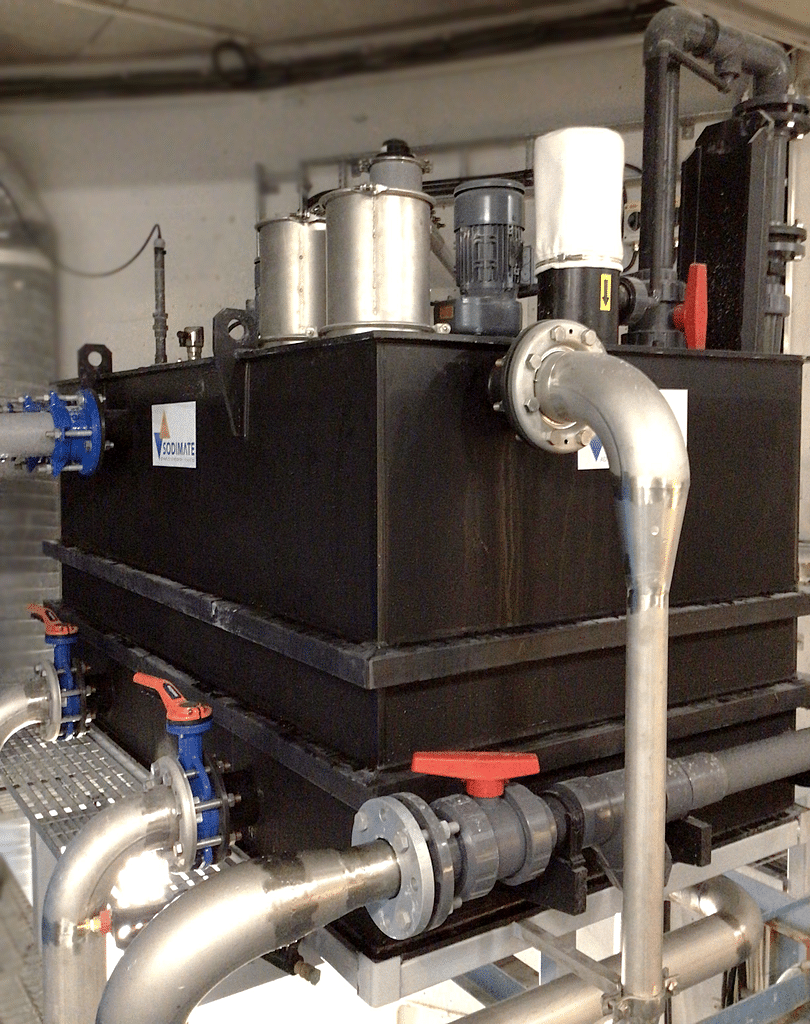

Sodimate helps you find a feeder that will suit your operational needs. Our highly qualified team of engineers design state-of-the-art loss-in feeders that fit perfectly with your goals. We are experts in integrating various standardized equipment and designing a custom solution that meets the customer’s needs. Avoid costly do-overs and choose loss in weight system by Sodimate.