Sodimate has just supplied a hydrated lime storage, discharge and metering unit for a flue gas treatment application at CBR factory in Belgium. CBR is a member of the Heidelberg Cement Group, leader in clinker production.

In the clinker (cement base material) manufacturing process, raw materials are cooked using fossil energies (coal) but also alternative combustibles (fluffs, dried sludge, animal flours etc.)

This process produces flue gas containing Sulphur (So4) and chlorine (Hcl), which are removed by 2 hydrated lime injection units, located before the kiln and at the bag house filter inlet.

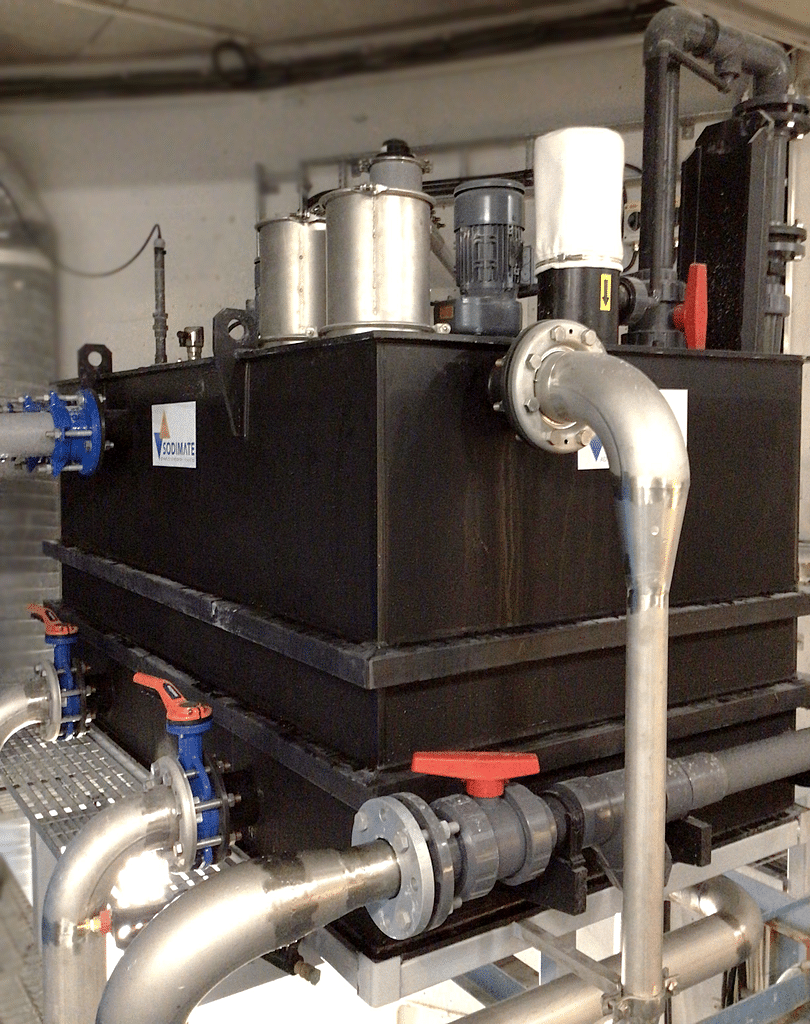

The unit that Sodimate provided concerns this second injection and includes a 60m3 polyester silo, an arch breaker ZCD400 and a screw feeder type DDMR 100 whose capacity is 200 to 1000 kg/h of hydrated lime.

- The unit, also designed to work in continuous in case the other injection unit fails, is used daily as a complementary injection in order to remove the residues of chlorine still present in the flue gas, just before it enters the bag house filter.

- The pneumatic conveying device installed by CBR conveys and sprays the lime in order to optimize the contact lime/pollutants. A specific screw feeder outlet was installed to connect the pneumatic duct directly onto the screw feeder without using any intermediate system such as a rotary valve.