Case study – United States

Solving an inconsistent lime feeding issue for a major uranium conversion facility using Sodimate’s built-in mechanical bin activator (arch breaker)

A major uranium conversion facility dealing with nuclear waste management, based in Illinois in the US, turned to Sodimate Inc. to fix one of the most common malfunctioning issues with Lime Handling Systems, i.e. an erratic unloading of the lime due to clogging. The facility needed to replace its old dysfunctional equipment with a more efficient one to comply with newly applicable quality standards by the Environmental Protection Agency (EPA). The facility’s Process Engineer, Luke Richardson, called on Sodimate’s industryleading technology and expertise and the clogging issue was fixed with optimal results by retrofitting Sodimate’s patented DDS400 Bin Activator onto its lime silo, which allowed for the seamless lime feed his plant needed to reach the required standards and avoid decommissioning.

CHALLENGE

In 2015, the Environmental Protection Agency (EPA) modified the hazardous waste management permit held by this key player in the nuclear fuel cycle for its Illinois plant to comply with newly proposed fluoride limits in each of its outfalls. The plant proposed a number of upgrades to its Environmental Protection Facility (EPF), amongst which was the replacement of their lime feed system to meet the latest required standards.

The problems had arisen from the incapacity of feeding the lime consistently into the system. One of the main challenges with treating lime is its increased density due to excessive moisture, which causes compaction at the bottom of the silo, resulting in erratic unloading and the impossibility to maintain a constant flow. “The first report I got from my operators when I started the project was that we couldn’t consistently feed lime into our system. Our operators had to use sledgehammers all the time and beat the side of the silo and that was a laborious process, even if it worked,” says Luke Richardson.

The plant had learned hard lessons from its experience using vibrators, which was clearly not the right solution: “The system produced air blowbacks into the cone, fluidizing the silo and that’s how we would ensure the flow of the lime. The lime would drop into the cone towards a split silo discharge downstream; one side went to a rotary valve, and the other fed to a screw conveyor and that dropped into a slurry tank. Due to lime absorbing ample moisture and rat holing, it made big voids in the silo. In the past, we had tried vibrators to monitor the silo: the reasoning behind it was that if a little vibration was good, a lot of vibration was better, so the operators would leave the vibrators on and what that would do was to concentrate lime at the bottom and it was even more difficult to create a flow once that happened,” explains Luke. Pneumatic conveying was even considered but using this system would have created a whole another environmental dust issue and was disregarded.

THE FIRST REPORT I GOT FROM MY OPERATORS WHEN I STARTED THE PROJECT WAS THAT WE COULDN’T CONSISTENTLY FEED LIME INTO OUR SYSTEM. OUR OPERATORS HAD TO USE SLEDGEHAMMERS ALL THE TIME AND BEAT THE SIDE OF THE SILO AND THAT WAS A LABORIOUS PROCESS, EVEN IF IT WORKED […]

LUKE RICHARDSON

PROCESS ENGINEER

SOLUTION

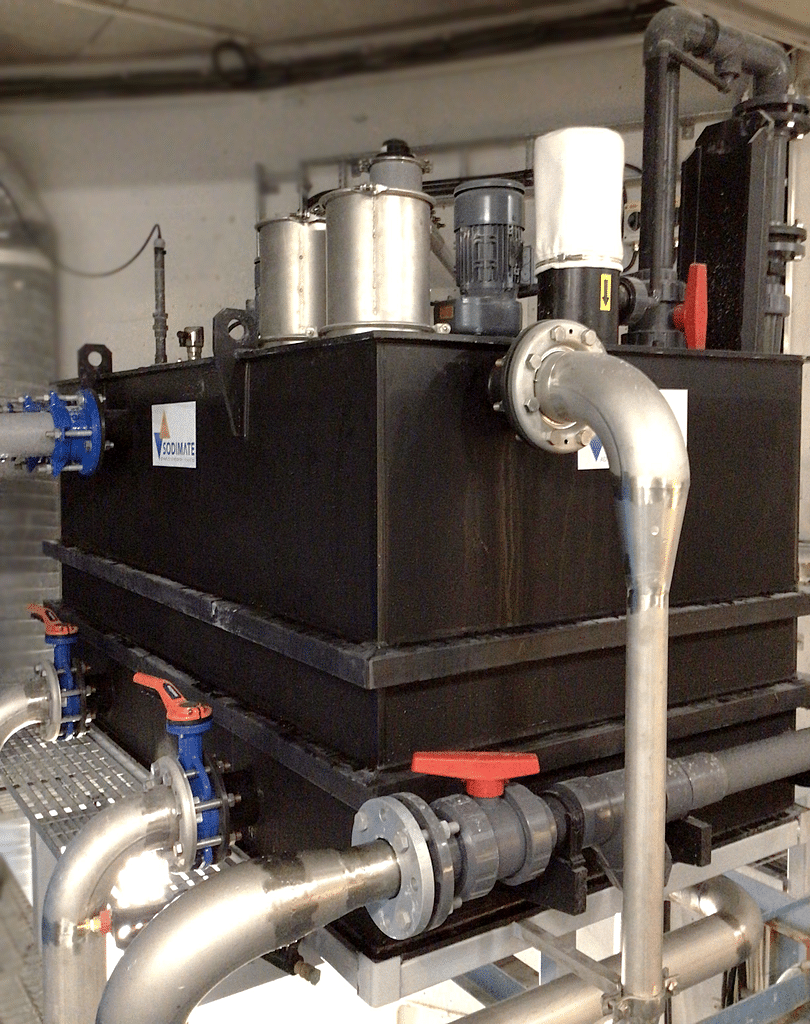

A high-performance calibrated equipment was needed. This is where Sodimate’s DDS 400 came into play. The DDS 400 offers one of the strongest, most reliable discharge systems available on the market. Other existing lime discharge systems require multiple parts, have limited silo integration or are not capable of sustaining multiple feeds at once.

Its unique double screw feed and arch breaker is mainly what gave Sodimate the edge over its competitors. “The operational principle of the screw feeder but also the built-in arch breaker are the factors that came into play when weighing the options,” says Luke. “It seemed more reliable than everything else I found in the industry. […] It just seemed that it would be more reliable and less maintenance than the other options out there. I thought that the double screw feed ‘mentality’ whereby you feed this screw to another screw and every time you shut down that one feeds out to keep moisture from blocking out your first screw was really fluid. And it works great; our system has held up and done really good. The only moisture that gets in results from what happens at the loading site, and when they use pneumatic conveying for offloading trucks […] and that’s the only added moisture. Our old system was blowing air into the cone and that was adding moisture constantly and lime is bad for rat holing, making domes and creating bridges on itself,” admits Luke.

Another decisive factor was the effortless solution Sodimate offered by providing a whole system, which is Sodimate’s competitive edge, saving the customer from having to purchase individual parts from each manufacturer.

Luke, above all, needed a reliable system that had proved its worth: “One of the things I wanted early on was to get an industrial reference and Sodimate set me up with a power plant in Indiana they had worked with and I went to do a site visit, saw the system, got some more feedback from the guys that were actually handling their system and they told me the same stories that I heard every day from my operators [Editor’s note: the compaction at the bottom of the silo due to excess moisture]. That was pretty handy to have: somebody was using the system and it was working,” states Luke.

Sodimate’s experience and professionalism stood out once again as far as installation and support were concerned. “The Sodimate tech team that worked on this project with us bent over backwards to help with the support and get the documentation that our plant actually required to get a quality project through. The team was very good to work with as far as getting contact with the actual silo manufacturer. We put up a process specs and they had all the equipment to the point that it met all our specifications. The capital process we have is very rigorous and requires appropriate documentation for everything. When it came on site, the tech guys were there to help us start up and were there for the whole process and they explained to the installation team how the arch breaker worked and helped trained our operators before we launched it,” Luke points out.

THE OPERATIONAL PRINCIPLE OF THE SCREW FEEDER BUT ALSO THE BUILT-IN ARCH BREAKER ARE THE FACTORS THAT CAME INTO PLAY WHEN WEIGHING THE OPTIONS […] IT SEEMED MORE RELIABLE THAN EVERYTHING ELSE I FOUND IN THE INDUSTRY. […] MORE RELIABLE AND LESS MAINTENANCE THAN THE OTHER OPTIONS OUT THERE.

LUKE RICHARDSON

PROCESS ENGINEER

RESULTS

Installed under a 3,600 ft³ silo, the Sodimate mechanical arch breaker not only discharges the lime by preventing bridging and compaction, but it also doses the lime at a variable and adjustable feed rate into two lime slurry tanks. The two independent feeding screws have the capability to transfer the lime at different feed rates. An injector follows each feeder in order to protect the powder from the moisture in the slurry tanks. The two slurry systems are totally independent. The two tanks have 1,000, and 500 gallon capacities respectively. The entire lime handling system, including the silo, discharge, and feed equipment is mounted on load cells for inventory control. The connections to the rest of the downstream equipment were made flexible to improve the accuracy of the load cell readings.

“In the past we didn’t need the kind of control we have to have now because of the new requirements. Each of our outfalls that go to the main outfall now have to meet the same specifications as the total flow. What that meant was that I would have to run with a fluoride concentration of 15 parts per million (ppm) […] We’ve been able to meet our new specs to keep the ponds running. The system is up and running and we’ve had minimal issue if any. It works great for that part of the process. Sodimate has been the most responsive company I have worked with in my career. Our team here has been impressed with how well it works,” concludes Luke.

INSTALLED UNDER A 3,600 FT³ SILO, THE SODIMATE MECHANICAL ARCH

BREAKER NOT ONLY DISCHARGES THE LIME BY PREVENTING BRIDGING

AND COMPACTION, BUT IT ALSO DOSES THE LIME AT A VARIABLE AND ADJUSTABLE FEED RATE INTO TWO LIME SLURRY TANKS.

TO LEARN MORE ABOUT SODIMATE’S MECHANICAL ACTIVATOR DDS 400, VISIT : HTTPS://SODIMATE-INC.COM/MECHANICAL-BIN-ACTIVATOR/ OR CONTACT OUR CHICAGO OFFICE.