Europe produces about 9.3 million tons per years of dewatered sludge from wastewater-treatment plants (WWTP). Commonly the produced sludge is mixed with calcium oxide or quick lime (CaO) for agricultural use as fertilizer.

Quicklime/sludge stabilization advantages

- Increase sludge dry solid content (%DS) up to 30%

- Increase PH over 12 to control the pathogens activity.

- Reduce or eliminate bacteria thanks to the calcium oxide and Sludge’s water exothermic reaction (temperature raising up to 60°C or 140°F) control odors generated from anaerobic fermentation increase sludge storage time.

- The result is a stabilized sludge, rich in nutriments and organic matters acceptable for fertilizer usage.

Lime/sludge stabilization overview

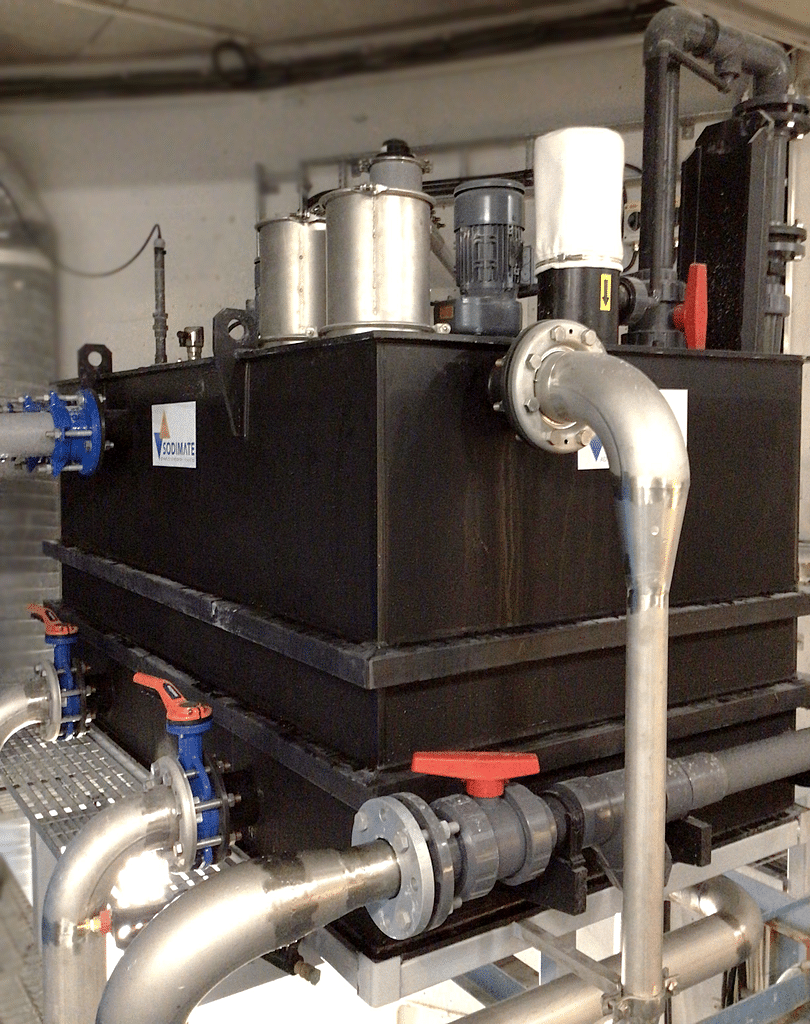

The quicklime, added to the sewage sludge, is generally delivered by 28 Tons bulk truck. The quick lime is then discharge pneumatically into a storage silo sludge resulting from waste water treatment plant are generally close to 8% DS and need to be dewatered with dewatering equipment such as sludge belt press, centrifuge, frame press or else to be either stored or stabilized. Lime is discharge by Sodimate’ s unique mechanical silo unloader “arch breaker DDS 400” which also include and isolation valve, a hopper and volumetric feeder. The lime is then injected with the dewatered sludge into a dual paddle sludge mixer (MBV). And transported into bin, storage area or directly into trucks via belt conveyors or sludge conveyors.

Downstream sludge stabilization process

In the case of a downstream stabilization process, the quicklime is added into an agitating tank then pumped/transferred into the dewatering equipment and transfer to the sludge storage point. The main different is the type of quick lime called “delayed” lime which basically only reacts (exothermic reaction) about 20 min after being added to the pre-dewatered sludge. A sturdy mixing and appropriate sludge lime volume ration ensure a homogenous treatment and reaction.

Over its 40 years of experience in Water and waste water application Sodimate has develop reliable and effective bulk handling system for the sludge stabilization process and handling. For any post treatment application or for any additional information please contact us at commercial@sodimate.com

Sodimate is able to design your installation of pre or post stabilization, you can send us your requests using our contact form, by sending us an email at commercial@sodimate.com or by contacting us by phone at + 33 1 30 10 61 70.