Arnfield Water Treatment Works is located west of the City of Manchester in the North of England. This works supplies 120 mega litres of fresh water each day. The water is treated at this site with hydrated lime (Sodium Carbonate) from a large storage silo, which is built into the building. The lime works were in urgent need of update as the original plant, installed in the 1960s, was very unreliable, with very high running costs. Regular blockages and spills required a lot of maintenance work, and also caused much lime powder to be wasted.

To replace this plant on a budget was proving extremely difficult. The layout of the site is poor, with little space for incorporation of new equipment. Also, the existing concrete lime storage silo had to be retained & refurbished.

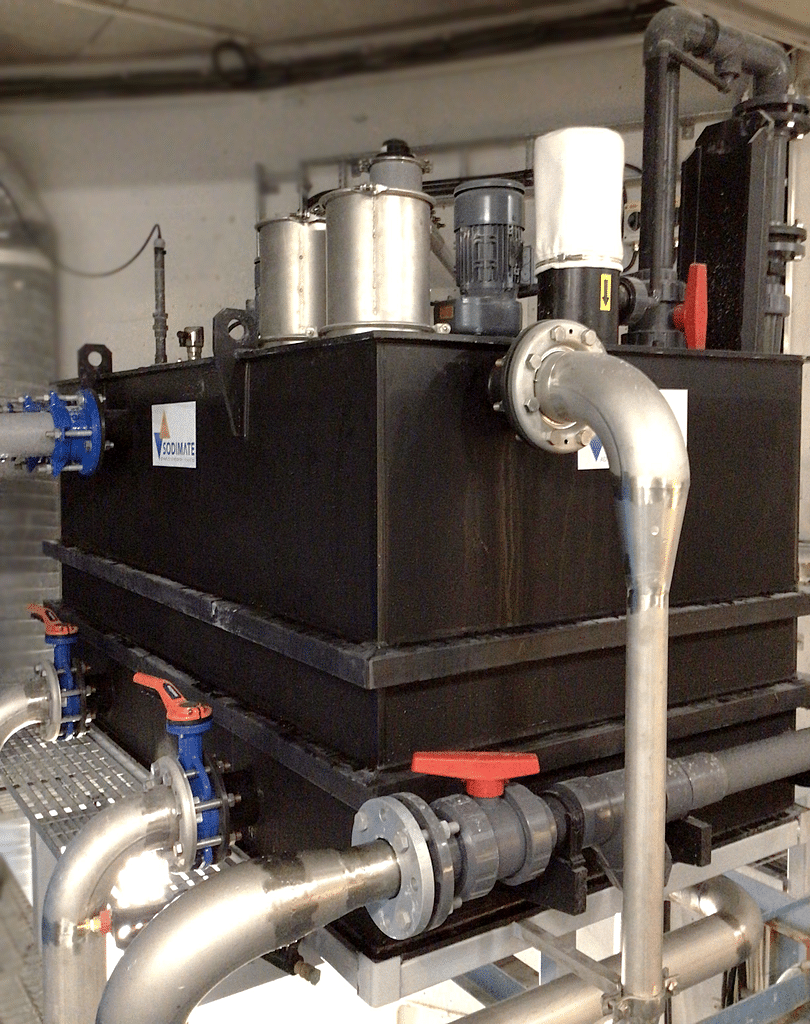

In 2013 SKE Solutions Limited, the main contractor, used careful design to improve silo discharge and powder mixing. This was achieved using unique ‘Sodimate’ arch breaking systems, both for silo discharge and for individual hoppers on the mixing tanks. Long horizontal and vertical powder conveyors were also supplied by Sodimate. Some conveyors even had to pass over the top of the silo! The Sodimate plant design has eliminated blockages, and keeps the lime powder flowing freely, resolving the previous problems. The lime is now fed to 4-off modern mixing tanks, which use simple Sodimate powder injectors for accurate mixing of lime powder with water with no possibility of blockage.

The plant now uses 90% less lime powder than before, due to the efficiency of the positive discharge metering system and the mixing tank accuracy. The investment at this site has now resulted in a reliable, modern, dust free system for the future.

The Client Project Manager is very pleased that an excellent job has been completed in what was a very difficult situation.