The Moulins-lès-Metz WTP which belongs to the Water Syndicat of the Messine Region (SERM), has increased its production capacity since 2022, from 60,000m3 to 90,000m3 per day. This optimization aims to guarantee a stable supply of drinking water that complies with total organic carbon (TOC) standards for subscribers and local authorities connected to the syndicat network, serving over 200,000 inhabitants on a daily basis.

Thanks to these improvements, the plant is now able to meet the temporary needs of neighboring regions, securing the drinking water supply of over 400,000 inhabitants – a significant part of the Moselle department.

To modernize the infrastructure, teams from Société Mosellane des Eaux, SERM‘s delegate, commisionned OTV. The integration of an Actiflo®carb process was at the heart of this modernization, making it possible to effectively treat the Total Organic Carbon (TOC) of the river Rupt de Mad, by means of powdered activated carbon decantation, using microsand in the process.

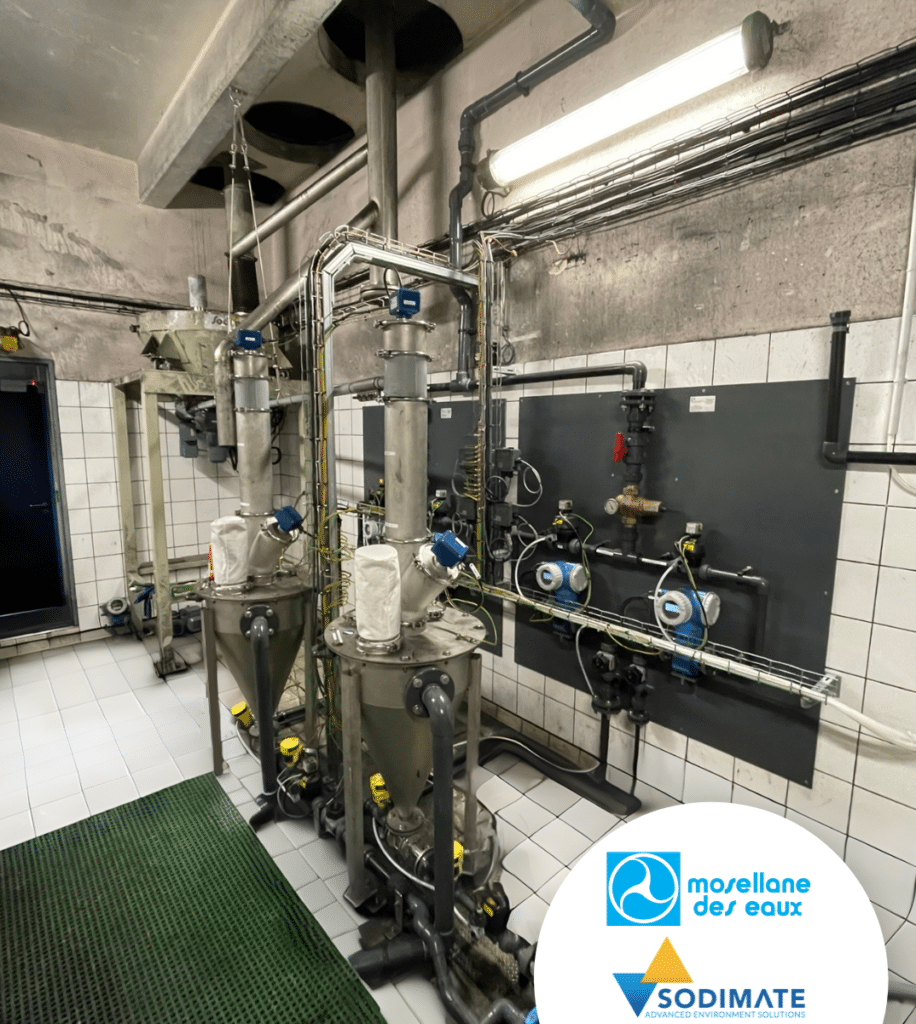

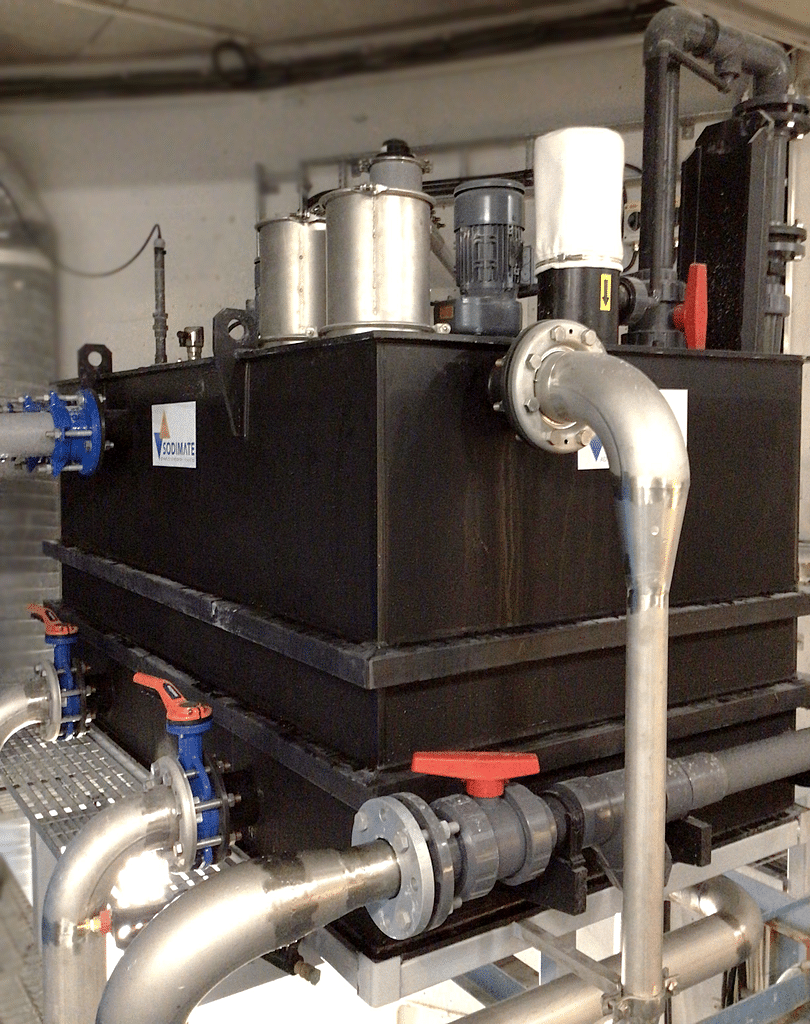

Sodimate was asked to help modernize the plant, replacing the discharge and dosing unit, the powder activated carbon (PAC) preparation and storage tank, as well as the peristaltic injection pumps. The aim was to introduce a slurry eductor transfer technology offering unrivalled ease of operation, optimized compactness, and significant reductions in maintenance costs.

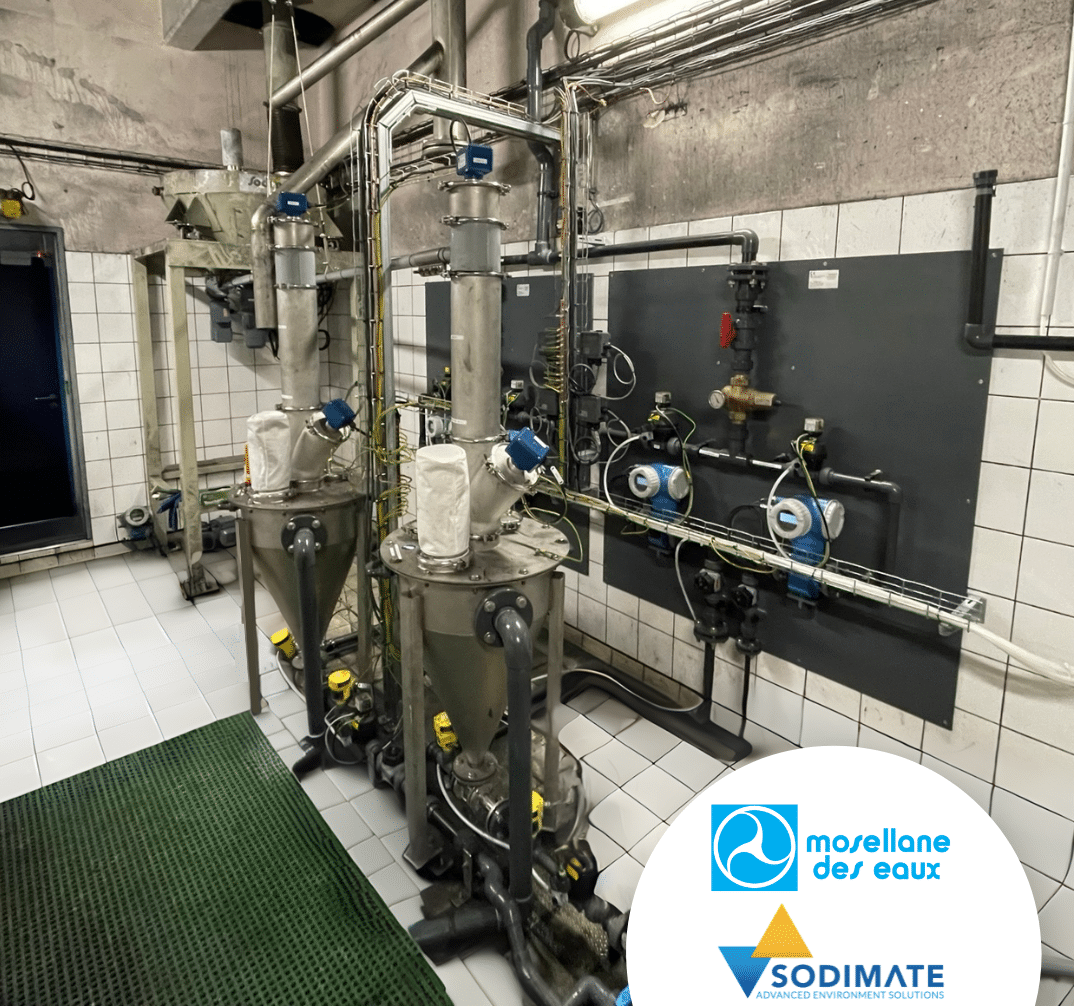

The implementation of the new water treatment system, with the introduction of two screw feeders and two slurry eductor transfer systems, represents a significant step forward for the plant optimization.

This configuration offers several significant advantages, reflecting a commitment to operational efficiency and environmental sustainability.

- Increased reliability: as a transfer system, slurry eductor are renowned for their robustness and reliability. Unlike traditional pumping systems, slurry eductor have fewer moving parts, reducing the risk of breakdowns.

- Dosing efficiency: The use of dosing screws for activated carbon, placed under a buffer hopper on load cells, enables precise dosing control. This precision is crucial to efficient water treatment, ensuring that the optimum amount of activated carbon is used to treat impurities without wastage.

- Reduced maintenance costs: The simplified design and reduced mechanical parts of slurry eductor significantly reduce maintenance requirements and service costs. This translates into long-term savings for the plant, while ensuring consistent treatment system performance.

- Turnkey project: The complete dismantling of the existing equipment and the installation of the new equipment. As well as the modification of the piping to supply the slurry eductor with drinking water, were carried out in an integrated manner. This “turnkey” project, including studies, ensures a smooth transition to the new system and minimizes operational disruptions.

This upgrade enables the plant to effectively treat total organic compounds as well as some of the pesticides contained in surface water, thanks to the activated carbon injected into the Actiflo®carb process.

Impact on Operations

This project illustrates the importance of careful planning and execution when modernizing critical infrastructure. The choice of this integrated approach guarantees an immediate improvement in treatment capacity at the Moulins-lès-Metz plant.

The integration of this advanced system also underlines SERM’s and Société Mosellane des Eaux commitment to state-of-the-art water treatment solutions. By improving reliability and efficiency while reducing maintenance costs, the Moulins-lès-Metz plant is optimally positioned to meet future challenges, including rising demand for drinking water and increasingly stringent environmental standards.

With this new treatment process, SERM is preserving its resources, improving treatment performance and sustainably preparing the future of water in its territory and beyond.

https://www.linkedin.com/feed/update/urn:li:activity:7168900219441475585