What is an Automatic Bulk Bag Discharger?

An automatic bulk bag unloader station is a one-stop solution for potable water treatment, wastewater treatment, gas treatment, seawater desalination, and pulp and paper treatment. It is adapted to use with flexible containers of different volumes and provides for complete and automatic container discharge into a reception hopper with no subsequent product compaction. Big Bags can either be loaded with a crane, a forklift, or the crane integrated into the system depending on whether you’re using a standard or auto-load version of the Big Bag.

Which Industries Use the Bulk Bag Discharger Station?

There are quite a few industries that make use of this station the most, and they include:

• Wastewater treatment whereby lime is used for sludge stabilization to create a product that can be used on the land application in case of acidic soil. The sludge is stabilized to reduce its ferment ability and odors, reduce its volume by reduction of its water content, and kill pathogens.

• Incinerators of various waste, including households and hospitals. The gases produced contain different pollutants like dioxins and heavy metals, which must be treated with a reagent injection to reduce the content of pollutants to a legal level of emissions.

• Drinking water plants to remove pesticides, nitrates, cleaning agents, and other waste from the water to make it safe for human consumption.

• The pulp and paper industry to treat any wastewater produced before reusing or releasing it into the environment. Lime is also used in the process as a pigment to improve the quality of the paper.

• In the sugar industry, a preparation of lime milk is used to purify the cane juice so that the resulting product is free of impurities.

• In seawater treatment plants, lime is used in the process of reverse osmosis to adjust pH and remineralize the water before it can be consumed as freshwater.

What Options Does an Automatic Bulk Bag Discharger Station Have?

With an automatic bulk bag discharger station, you have the following operating options:

Isolation Diaphragm Valve

The diaphragm valve is used for the reusable bags with a spout. The aim is to block the powder after opening the node in order to avoid the dust emission while the operator open it.

Dust Collector

This is the device that will draw all dust and particulates through its filter. Release purified air and the dust can be emptied once the hopper in which it collects is full.

Big Bag Opening Knife

Big bag knife are used for non reusable big bag with flat bottom. Using this apparatus, you can stand at a safe distance from the bulk disposal bag while opening it. It increases safety as the big bag can be opened without the user having to have their arm under the suspended large bag.

Weighing Unit

This makes sure that the product always stays within the right limits and checks how much powder is remaining.

Autoload Station with Integrated Crane

The integrated crane allows for an extra option when loading the Big Bag so that if there is no crane or forklift available, operations can go on.

Benefits of Using Automatic Bulk Bag Discharger Station

When you use the automatic bulk bag discharger station from Sodimate, you get to experience the following benefits:

Suitable for Containers of up to 2T

The variety of sizes and suitability of using up to 2T container sizes means that you have a great likelihood of getting your needs met, whatever your industry or scale.

Easy to Use

The automated system makes it easy to operate once you have the basic instructions down. It is therefore easy to train operators, and you stand to save a lot of time getting things done.

Direct Dosing From Container

Handling is a lot safer and faster for the operator thanks to the direct dosing. This increases accuracy because the user has total control over the amount of product that is dispensed.

Total Big Bag Emptying

The fact that a single operator can run all operations makes it faster, and because of full compliance with health standards and regulations, it is very safe to run.

Optimized Dust Control

The dust control features improve cleanliness and thus, makes the area of operations safe for everyone by not releasing the particles in the air that can cause health issues when inhaled.

Efficiency and Safety

The automatic nature of this system coupled with the safety features makes it eligible for the future. It will help you save time and effort while getting the job done effectively so that you can process more products in a shorter time. The instructions for using it are clear and straightforward, and its flexibility avails plenty of options for use.

Automatic Version Available (with Integrated Crane)

An automatic version is available that has an inbuilt crane. This makes it usable even in the absence of forklifts and additional cranes. The free-standing unit can be operated efficiently as long as the operator follows the instructions to use it safely.

With the use of bulk bags constantly increasing, you need to get a solution that will be both safe and efficient. Complete, automatic discharge into the reception hopper with no compaction makes for an even flow of product so that everything works as it should; gently and evenly. If you are looking around for a bulk bag discharger that will revolutionize the way you handle product and waste, give our automatic bulk bag discharger station a go.

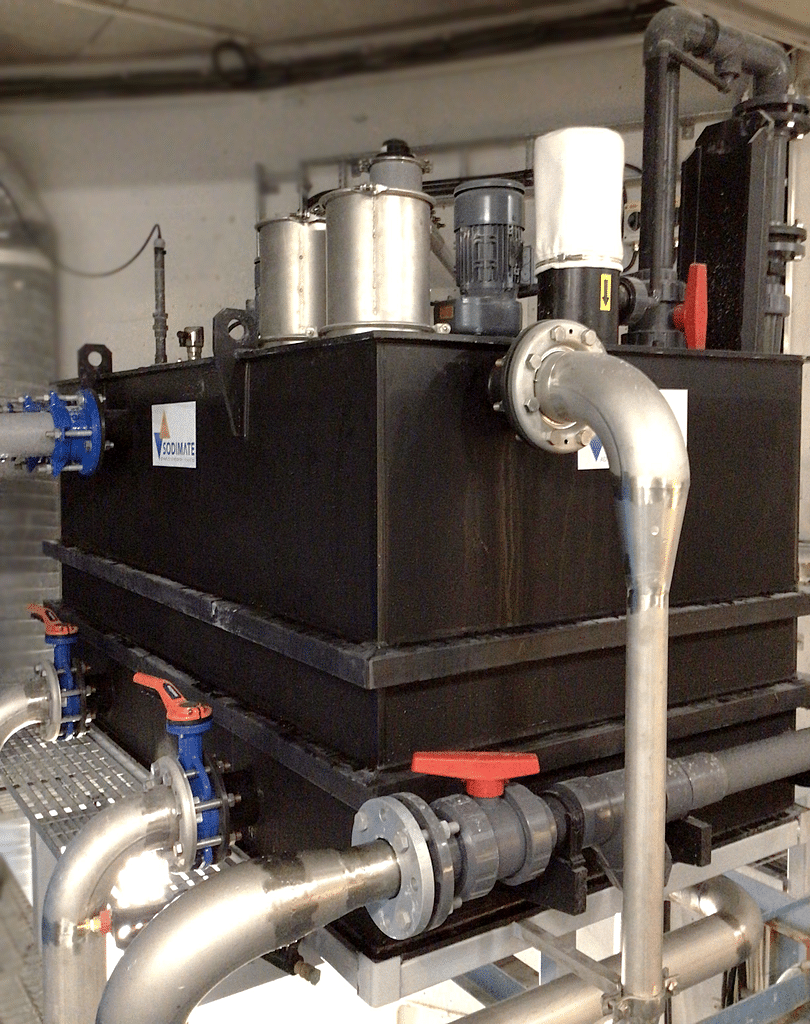

Sodimate’s bulk handling and processing equipment offers you efficient and reliable systems that are also more economical than purchasing the necessary equipment separately.