Egger calls on Sodimate to guarantee the environmental performance of its Rambervillers plant.

The Egger factory in Rambervillers, in the Vosges, receives 700,000 tons of raw wood every year, which it transforms into 600,000 m2 of decorative panels and complementary wood-based products. It supplies furniture manufacturers, interior designers, architects, and DIY stores in several countries, including France, Germany, Austria, Switzerland, Benelux, and Italy.

The international Egger group – of Austrian origin – is pursuing an ambitious environmental strategy, ranging from forestry to waste recycling. Including sustainable forest management, full product traceability (ISO 38200 standard) and circular economy. In Rambervillers, this involved treating fumes from the boiler with lime. Egger called on Sodimate to design, manufacture and deliver a complete system in just four months.

Certified to ISO 14001 environmental standards in 2016, the Rambervillers plant burns all waste in a 55 MW biomass boiler. “We are practically autonomous because we produce all the thermal energy necessary for the process, as well as a good part of our electricity thanks to a steam turbine of 9.6 MW” explains Pascal Labourdique, the energy manager of the site. Considered an incinerator, and not as a simple heat generator, this boiler must comply with very strict regulatory constraints in terms of the discharges. The contents of dust, metals, HCl, HF, SO2, VOC, CO, but also dioxin and furans, in the fumes of this type of installation are indeed very severely limited. However, the three hundred (300) tons of waste burned every day in Rambervillers contain both wood and plastic (edgebanding). Despite a boiler dating from 2018 and at the top of the state of the art, as well as a chimney filter replaced in 2020, the levels of hydrochloric acid (HCl), and sometimes sulfur dioxide (SO2), in the fumes still exceeded regulatory limits. The Regional Directorate for the Environment, Planning and Housing (DREAL) standards required the implementation of a more rigorous process.

The well-known solution consists in treating the fumes with lime, which captures the pollutants by adsorption. The soiled lime particles are then stopped by a filter. “Our technical teams sketched out a solution with a large lime producer. This company then advised us to turn to Sodimate to produce the treatment system. We thus met these real specialists in the handling of powdery materials, with whom we did business” Pascal Labourdique vividly recalls.

A tailor-made solution.

In the Rambervillers biomass power plant, the fumes leaving the boiler pass through a duct preceding a large bag filter. The latter retains more than 99.9% of dust. Finally, a chimney rejects hot gases into the atmosphere. It was therefore at the level of the sheath that the lime had to be injected.

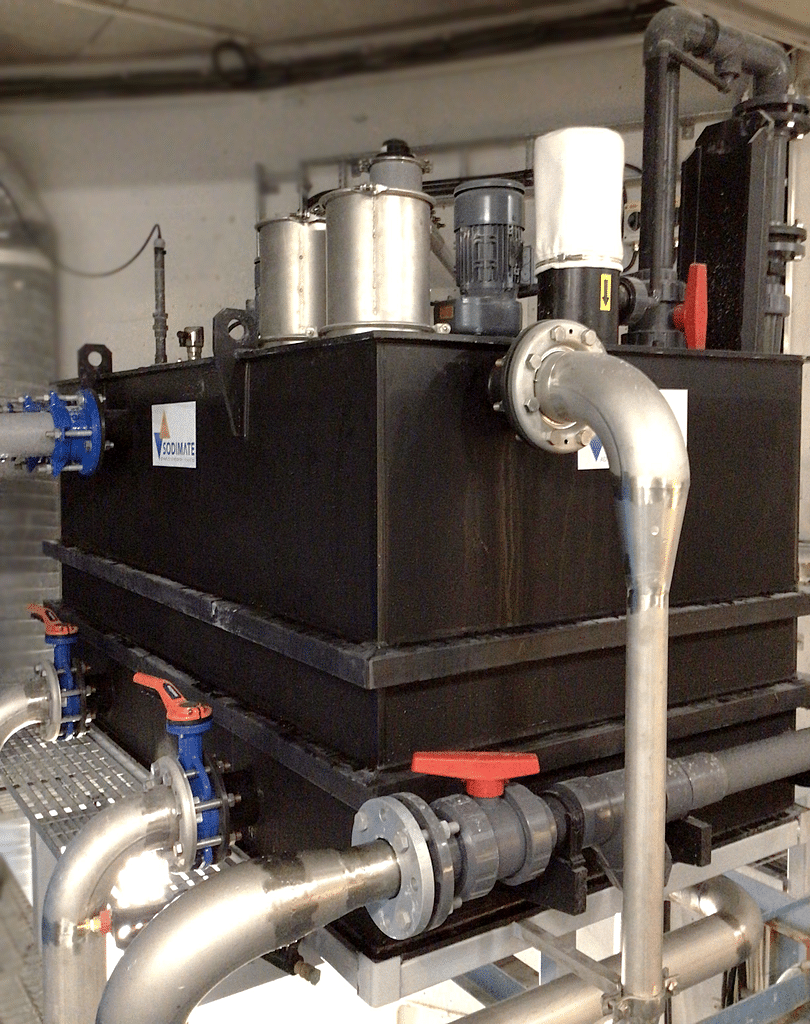

Sodimate offered a complete solution including:

– a cylindrical-conical storage silo. This polyester unit, 17 meters high and three inside diameter, offers a storage volume of 80 m3. It can thus contain up to 40 tons of powdered slaked lime – with a maximum particle size of 300 µm in the case of Rambervillers. The assembly is equipped with an outlet cone, a mechanical arch breaker and pneumatic hammers to lower the lime, level probes and a weighing system. As well of course as all the required safety and inspection equipment.

– an extraction and dosing system, a flow regulation system and then pneumatic transfer of lime to the flow of smoke. It is at this level that Sodimate implements proprietary technologies, unique on the market.

– a control by PID loop: the quantity of lime injected always depends on the level of pollution in the fumes. The latter is measured by an HCl probe installed at the outlet of the chimney, the signal of which is sent in 4-20 mA to the regulator. The composition of the flue gases can indeed vary a lot depending on what the boiler is burning at a given time.

– the entire system is encased in sensors to ensure proper operation. Silo weight, lime level, rotation speeds of the different motors, pressures, etc.: everything is controlled by a control cabinet, to which is added a remote box allowing remote control.

Strong constraints, original technology

Relatively conventional in principle, the Egger installation must, however, meet specific requirements. The first constraint, economically obvious: inject at each moment the quantity of lime necessary, neither more nor less. This is where Sodimate’s main asset comes in: the dosing devouter, the only device on the market capable of performing silo emptying and lime dosing operations in one go. The Vosges installation couples a ZDM 400 turbine arch breaker to a DDMR 40 SCF metering unit. The assembly, equipped with all the necessary motors and sensors, is slaved to the HCl probe, the signal of which acts on a frequency variator controlling the gear motor of the metering unit. Depending on the instructions received from the machine, the mechanical arch breaker and feeder can send from 1.66 to 8.33 grams of lime per second, or from six to thirty kilos per hour.

It is also essential to distribute the lime supply evenly in the volume of smoke to be treated, which at this point reaches a temperature of 180 ° C. A polyurethane transfer pipe, leaving the silo, guides the lime over a length of 40 meters, of which 10 meters vertically, to the sheath. The lime is propelled by a blower fitted with a frequency converter. The pipe opens onto a steel injection rod penetrating to the center of the sheath. The reagent is therefore not injected at the periphery of the smoke stream but diffused in its very heart, which ensures a homogeneous mixture between the smoke and the lime.

Speed and confidence

After initial discussions in the spring, Sodimate representatives visited the Rambervillers site in July 2020 to refine their proposal. From the order date to delivery, it only took four months. In those four months Sodimate finalized the design, built and fully tested the installation in the workshop. The equipment arrived in mid-November on the Vosges site, the assembly was installed in two days. “After a day of empty tests, they put the installation into service. On the evening of the second day, the result was there” recalls Pascal Labourdique. Speed and punctuality are essential because Apave Alsace had already planned a discharge conformity check for November 25. Result of this inspection: the flue gases from the boiler now comply with the requirements. According to site officials, they have never exceeded regulatory thresholds since.

As per the Sodimate standard, the installation arrived with full technical documentation. “Sodimate is a large structure that knows how to do things: they provided well-made plans and a detailed technical document of more than a thousand pages. We had never received such documentation for an installation of this level” affirms Pascal Labourdique.