Preventing and repairing industrial silos blockages such as arching, tunnels flows, bridging or segregation, with Sodimate’s Mechanical Bin Activator.

Industries handling different chemical products may experience blockages issues in their silos. It’s important to understand the basic concepts implicated in a problematic flow to choose the right discharging equipment.

Silos can getting stuck and hold the powder, but they are necessary when the process uses few supplies and needs high dry consumption. The main issues observed are the creation of blockages such as arching, tunnel flows, bridging or segregation. Our solutions prevent their formation and have the ideal discharge scenario, known as “mass flow”.

What is the appropriate function of your silo ?

A vibrating bin activator, assembled at the bottom of the silo, acted as a discharge mechanism. It was associated with a rotary airlock as the feeder, running during the entire batching process. This could only supply a consistent feedrate if the density of the material was not altered by the vibrations. It was difficult to ensure an accurate and constant flow of powder in this configuration. The vanes of the rotary airlock did not cover with material generating the volumetric displacement to differ.

What is appearing in the silo that causes flow problems ?

Flow issues can cause a full blockage of the powder or an interrupted discharge under the silo resulting in inaccurate metering and results. A complete understanding of each product and their physical properties is compulsory to choose the right equipment. For the powders that do not flow easily, like hydrated lime, Sodimate supplies a silo merged with a Mechanical Bin Activator to guarantee a continuous discharge. We integrate a dehumidifier connected to the fill line if products are sensitive to moisture, like soda ash.

Types of problems

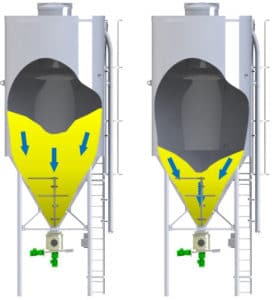

Tunnel flow or Chimney:

Also referenced as rat-holding, most of these issues appear when the flow is happening usually along the centerline, thus forming a vertical tunnel over the silo’s flange. When the silo is refilled the remaining powder is compressed up against the side, creating unflowable areas named “dead zones”. They frequently move in an avalanche form with blocks that clog the silo easily. This not only affects uniform discharging, but it also impacts the storage capacity of the unit./p>

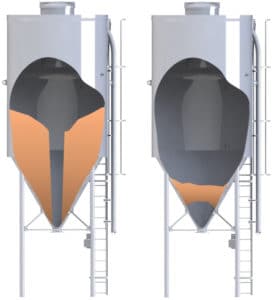

Arching or Bridging:

Totally interrupt the flow of the powder. This happens due to static pressure inside the silo cone because the diameter is gradually reduced from 14 feet to 8 inches. When the powder level is above four feet, the bridges and arches are naturally rectified.Nevertheless, the area below four feet requires the direct operation of Sodimate’s Mechanical Bin Activator. It prevents arching or bridging with a set of flexible rotating blades that deploy inside the powder, from the centerline to the cone wall.

Vibrations causes Segregation:

It happens when the silo experiences excessive vibration. The small and large particles separate from each other and separate the silo into several areas of densities. Some areas become more solidified, conducting to a blockage over the flange or an irregular dosage during unloading. For this reason, Sodimate doesn’t provide vibrating systems for silos. Preferably, our Mechanical Bin Activator ensures a gentle flow that incorporate a transition hopper under the silo, to stabilize the density and constantly feed the volumetric metering screws at 100%.

Blockages in Silos can also result from a combination of these issues.

If you are involving in any of these issues with your current unloading system, you maybe need a retrofit of your unloading system. Please contact us via this form, Sodimate would be delighted to propose a custom solution for you.