Home » Slurry Tank

SODIMATE now offers a tailor-made mixing tank to provide a complete system for lime milk slurry or activated carbon slurry preparation.

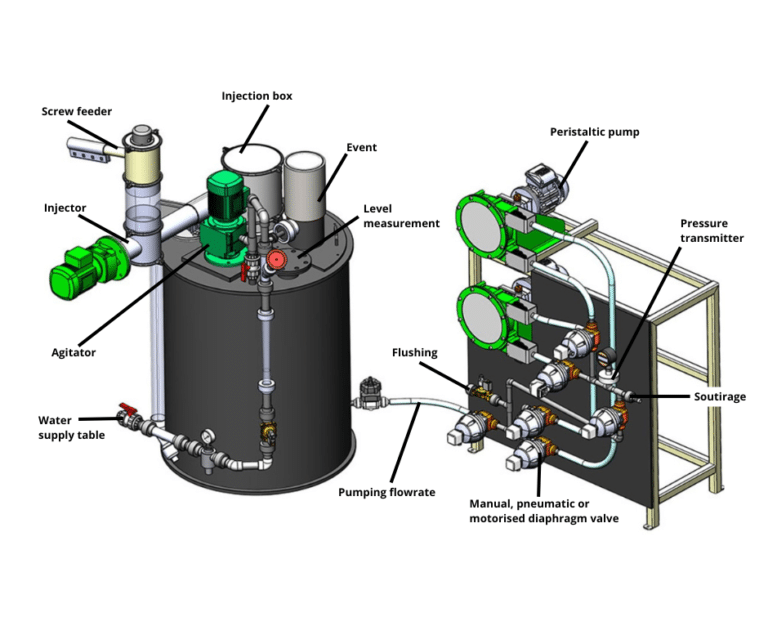

These tanks are made of black HDPE (high density polyethylene) and fitted with a mixer, a water board (with a solenoid valve), a level check system and spigots needed for pumping and emptying a lime milk loop. In order to prevent any dust emission, the dilution tank is completely closed. The system is available in sizes ranging from 500 to 2,000 liters to account for a variety of applications.

With systems intended for lime slurry or activated carbon preparation, Sodimate understands the importance of creating a fully homogenous solution. Our dilution tank is fitted with an agitator, ensuring that the hydrated lime or activated carbon particles are properly submerged, resulting in a quality mixture. Lastly, our tanks are fitted with an anti-vortex paddle in order to improve the overall quality and homogeneity of the mixture.

It’s also possible to adapt the dilution tank system to meet a variety of needs with the following additional applications:

SODIMATE offers tailor-made mixing tanks in order to provide complete systems for lime, activated carbon, micro-sand and other chemicals slurry preparation. (potassium permanganate, calcium carbonate)

Because the quality of suspension is a key factor in the success, Sodimate continuously looks for the following charcteristics:

These tanks are made of PPH (polypropylene), black HDPE (high density polyethylene), carbon steel or stainless steel and are equipped with all necessary instruments and accessories:

With a range of volumes from 500L to 10 000L, and even more on demand, Sodimate is in a position to provide a solution for every application, taking into account the chemical preparation time, the pumping throughout, the suspension concentration and the requested operation mode (continuous or batch modes).