Case study – Abidjan, Ivory Coast

Using the SODIMATE expertise to install a complete quicklime handling system. The operators used to manually empty up to 100 bags of quilcklime daily.

Ivory Coast Water Distribution Company (SODECI) has just started renovating its drinking water facilities. At some sites, the metering of the dry reagents is still done manually, with up to 100 25kg bags of quicklime per day to empty. This operation is extremely painful and presents risks for operators. Being exposed to these chemicals can be hazardous to their health.

To comply with ISO (International Organization for Standardization) standards, the project manager called SODIMATE to automate the handling of dry quicklime. The project goes from the storage to the lime slurry production process.

The challenge

With steady urban population growth, the major issues of sustainable development are sanitation and access to drinking water. This is the core business of SODECI, a partner of the Ivorian State since 1960 and the city of Abidjan since 1999 for water sanitation.

To meet this challenge, in 2017 SODECI began to improve its QSE (Quality, Safety, Environment) systems towards ISO 9001 and 14001 certifications within the Abidjan region.

In order to quickly comply with these ISO standards, SODECI began renovating its’ oldest treatment plants. The Riviera site in central Abidjan treats water from underground drilling sites for the residents of the Cocody district.

Underground water from Ivory Coast can have high amounts of CO2, which increase the overall acidity. This acidity must be neutralized to make the water drinkable. A possible solution for this is to inject lime into the water. The HO- ions from the quicklime will then neutralize carbon dioxide responsible for the acidity.

For these reasons, SODECI has decided to completely renovate the Riviera production site, starting with the lime slurry preparation and metering equipment.

During discussions held prior to the project, SODECI engineers have opted to use quicklime instead of hydrated lime.

The first advantage of quicklime compared to hydrated lime is the lower price point. Secondly, slaking quicklime creates less byproducts (grit) than processing hydrated lime.

SODECI has already experienced issues with grit, especially when it’s generated in large quantities with limited function. Quicklime appeared to be the best solution to address the aforementioned issues.

However, using quicklime requires the implementation of a slaking process, in order to use the lime onsite, before transforming it into the lime slurry needed for the treatment process.

In addition, the extinction of quicklime is an exothermic reaction. Operators must be protected from the heat. The solution chosen therefore had to minimize the interaction between the staff and the equipment.

Finally, lime is a clogging product which creates arches in the silo cones and irregular flow if a specific discharging system is not installed.

The solution

SODECI called SODIMATE and its 40-year expertise in powder products handling. Our technical department was fully engaged to find the solution that met all the challenges.

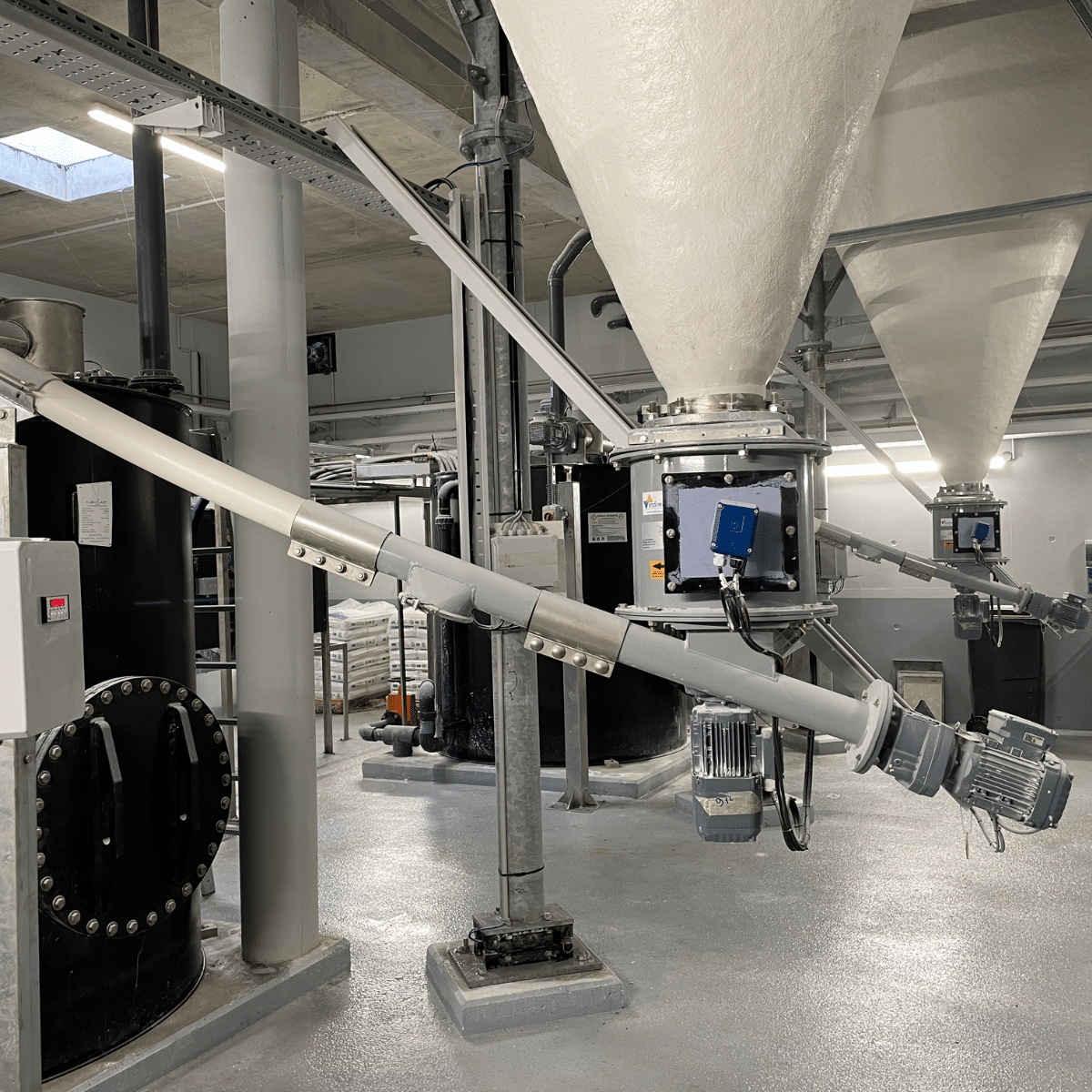

The quicklime is supplied in Big Bags. Sodimate suggested a Big Bag emptying station in order to quickly and automatically empty the bags to a 10m3 storage silo for more operational comfort.

The stand with an electric hoist allows to load the big bags on the drain table effortlessly. The inspection door on the hopper helps to open the bag spout and let the lime flow, all with minimal contact with the product.

The mechanical bin activator DDS 400, a flagship product in the Sodimate catalog, was chosen to ensure a constant and regular flow of the lime in the silo.

As mentioned in the United States Case study, the mechanical bin activator DDS 400 is a perfect solution against lime flow issues.

To meet the specific challenges of handling quicklime, SODECI chose Sodimate’s high-end quicklime slaking kit.

By considering all the parameters mentioned above, Sodimate has developed an innovative solution allowing the lime to be slacked easily and automatically.

Operating principle:

Sodimate’s mechanical bin activator meters quicklime to an epoxy-coated steel tank with a water supply system. The flowrate is regulated to get the right concentration for a proper lime slaking reaction. The tank has a mixer operating continuously. It is covered with a stainless-steel grid, spaced far enough from the tank to protect the operators from the heat released by the chemical reaction.

A temperature control of the mix is done continuously by a probe to check that the slaking is well done. This to ensure an optimal quality for the lime slurry.

Finally, a scrubber is installed on the tank roof to convey the vapors outside and protect the technicians operating in the room.

By overflow, the mix is transferred from the slacking tank to a dilution tank nearby. In this dilution tank, another water supply inlet dilutes again, thus creating a lime slurry directly usable in the treatment network. This new dilution has been set at 50g / L, but the customer can vary this parameter according to his needs.

Results

The SODIMATE expertise was able to meet all the challenges encountered to renovate the lime dosing station.

Under the 10m³ silo, the Sodimate mechanical bin activator allows a constant flow and an accurate quicklime metering. This is conveyed to our innovative slacking system which ensures optimal lime chemical reaction, at a concentration of around 250 g / L and at a slacking temperature ranging between 60 and 80 ° C.

The lime slurry is then diluted in our preparation tank installed for this purpose, before being pumped directly into the static mixer of the station via the peristaltic pumps also supplied by Sodimate. All water flowrates are regulated via the water skid also installed by us.

The installation has been running since March 2018 and allows a constant and automated lime slurry injection into the station’s static mixer. The acidity present in the underground water is then perfectly neutralized at the Riviera site in Abidjan. In addition, the strenuous activities have been reduced for the operators. They enjoy much better working conditions, and the risks associated with handling the product are reduced.