HCL removal with Dry Hydrated Lime Injection

Reduction of hydrochloric acid using Sodimate’s Pneumatic Transfer solution for Dry Sorbent Injection

California, United States

Sodimate upgraded an installation for a cement company located in the Mojave Desert, subject to control its emissions. The plant treats the fumes coming from a rotating kiln, which is the oven that cooks the raw materials to 2700 degrees Fahrenheit and transforms them into cement.

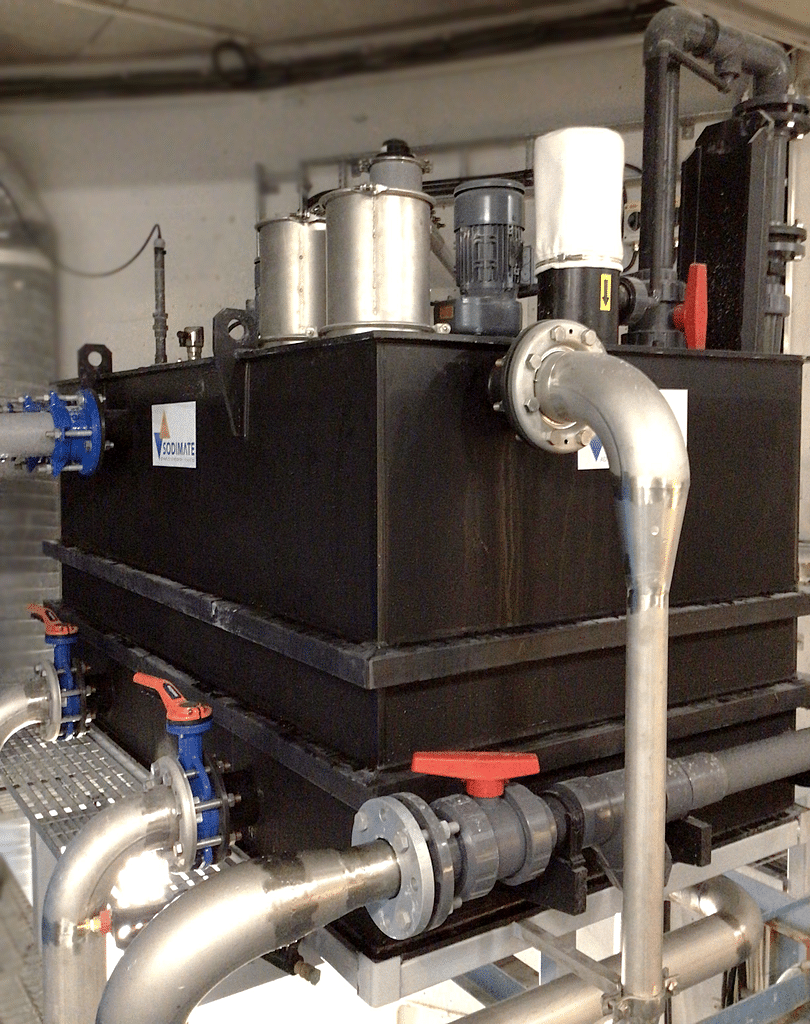

To achieve the reduction of hydrochloric acid [HCl], Sodimate designed and supplied a complete DSI system (Dry Sorbent Injection, a key pollution control technology) for hydrated lime. This solution upgrades a previous slurry tank process also supplied by Sodimate to mix the lime with water before its injection.

Discharging the storage unit

The storage unit is a 105 ton steel silo. This amount is the equivalent of 2.5 days of product. To ensure its complete discharge, the Sodimate’s patented Mechanical Bin Activator is constantly rotating inside the silo’s cone. Its set of steel flexible blades agitates directly the powder and brings it down to a stabilization hopper located at the bottom. Complementary and to meet the client’s request, Sodimate also supplied an air pulse system. This is a backup solution to ensure that the powder discharges correctly.

Dosing the lime with accuray

To dose the powder, a double metering unit including two volumetric screw feeders (one on duty, one on standby) is integrated after the discharging unit. These augers deliver between 8-30 lb per minute of product each, depending on their speed and frequency controlled by a couple of VFD (Variable-Frequency Drive). Sodimate gave the correlation between these values from its experience, then the data has been adjusted on site following the true physical properties of the powder.

Conveying to the Bag-House

The conveying system supplied integrates a pneumatic line that starts with 2 regenerative blowers: These units move air using non-positive displacement. They allow some air to pass over a blade and then forward using another blade. This is different from machines that use positive displacement and work by trapping air and forcing it to move.

A flexible duct delivers the powder to the-bag house. To avoid any accumulation of product in the elbows and clogging into the duct, the limit set on the hydrated lime’s speed is 65 ft per second.

A clean result for our environment

Finally the 36-stack bag-house fed with hydrated lime removes it downstream with a particulate matter control device. For modeling purposes, EPA (Environmental Protection Agency) estimates a DSI system with a fabric filter is expected to achieve 90% removal of HCl, although actual performance will vary by individual plant. As a result, nearly all particulates of the cement plant are eliminated, lowering the emissions.

Sodimate also supplies similar equipment that inject powders for Flue Gas Treatment. Powerplants and process furnaces use our pneumatic transfer systems against pollutants such as sulfur oxides as well as heavy metals, dioxins and furans.

by Guillaume Souchet, sales Engineer at Sodimate Inc.