The lime supply equipment of water utilities has traditionally posed challenges: the equipment has been outdated, operational reliability has been poor, and the use of lime has even been avoided due to technical problems. However, Kymen Vesi Oy decided to take up the challenge and update the lime alkalization system of the Kuivala plant in Utti to meet today’s requirements. The Sodimate equipment supplied by Hyxo Oy was chosen as the solution, which has improved the reliability of the process and brought cost savings.

The old equipment has come to the end of its life – how to ensure the uninterrupted operation of the water utility?

Household water in Southern Kymenlaakson is produced at Kymenlaakson Vesi Oy’s Utti artificial groundwater plant, which serves residents and businesses in the Kotka and Hamina regions, among others. One of the most important tasks of the water utility is to alkalize the water, which ensures the quality and usability of the water.

However, the equipment that had been in use for decades began to show signs of aging.

“The reliability of the old lime supply equipment was no longer at the level required by today’s water supply. In addition, getting spare parts started to be challenging,” says Jukka Pesu, a representative of Kymen Vesi.

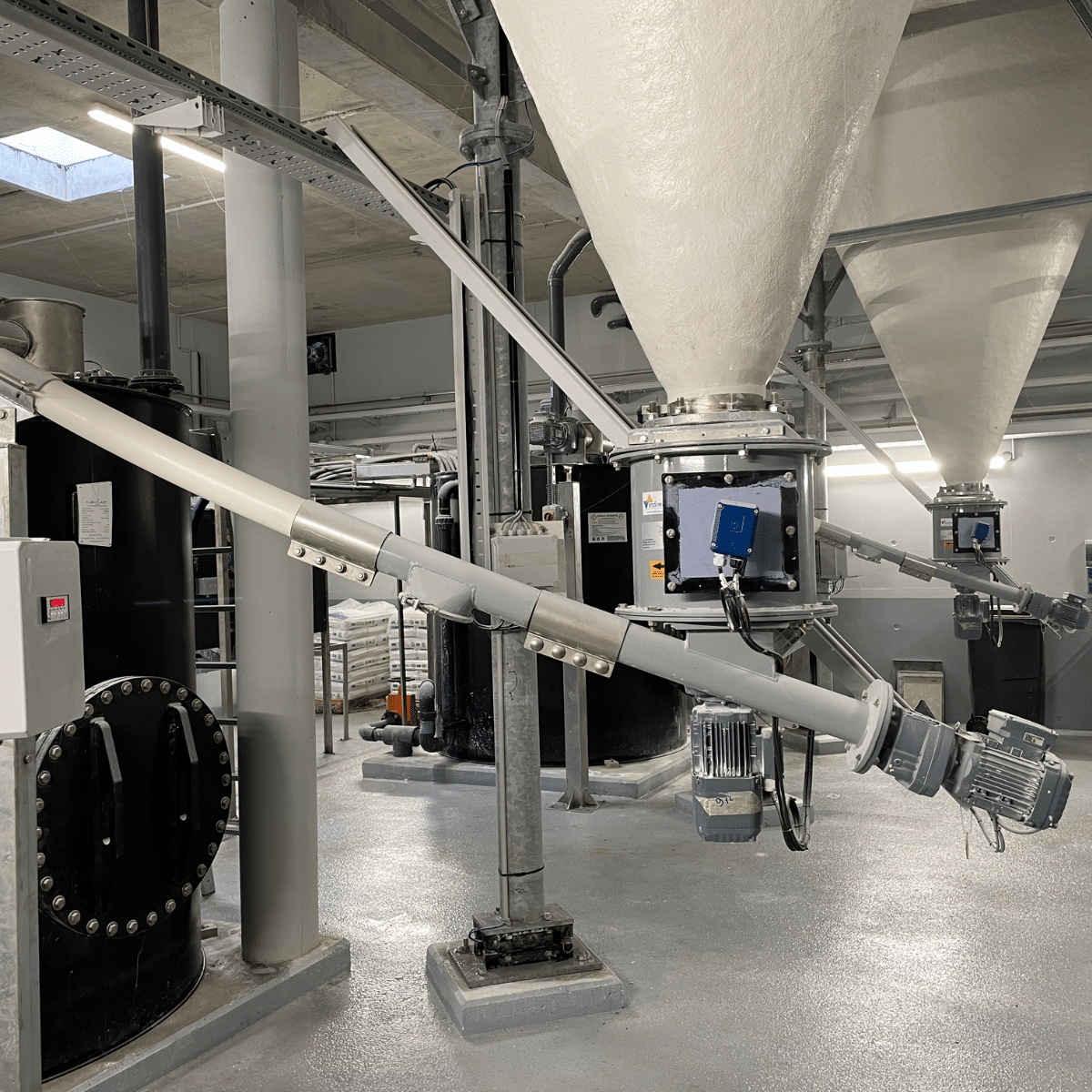

However, the plant’s operations could not be interrupted for the duration of the update. The solution chosen was a modern lime alkalization system implemented in cooperation between Hyxo Oy and Terco Engineering Oy, which was installed without process interruptions.

Why lime? A safer and cheaper option compared to lye

Traditionally, either lime or lye has been used in the alkalization processes of water utilities. Lye has been a popular option due to its ease of use, but there are also challenges to handling it – it is corrosive and poses safety risks.

“There have been bad experiences with the use of lime in the past, but they were mainly due to outdated technology. Today, lime alkalization is a safer and more economically viable solution,” says Kari Rusi, Product Manager at Hyxo.

Thanks to the Sodimate equipment, the use of limescale is not only more reliable but also more cost-effective. “If we look at the long term, for example a 20-year period of use, the use of lime is significantly cheaper than that of lye,” adds Ari Saari, CEO of Terco.

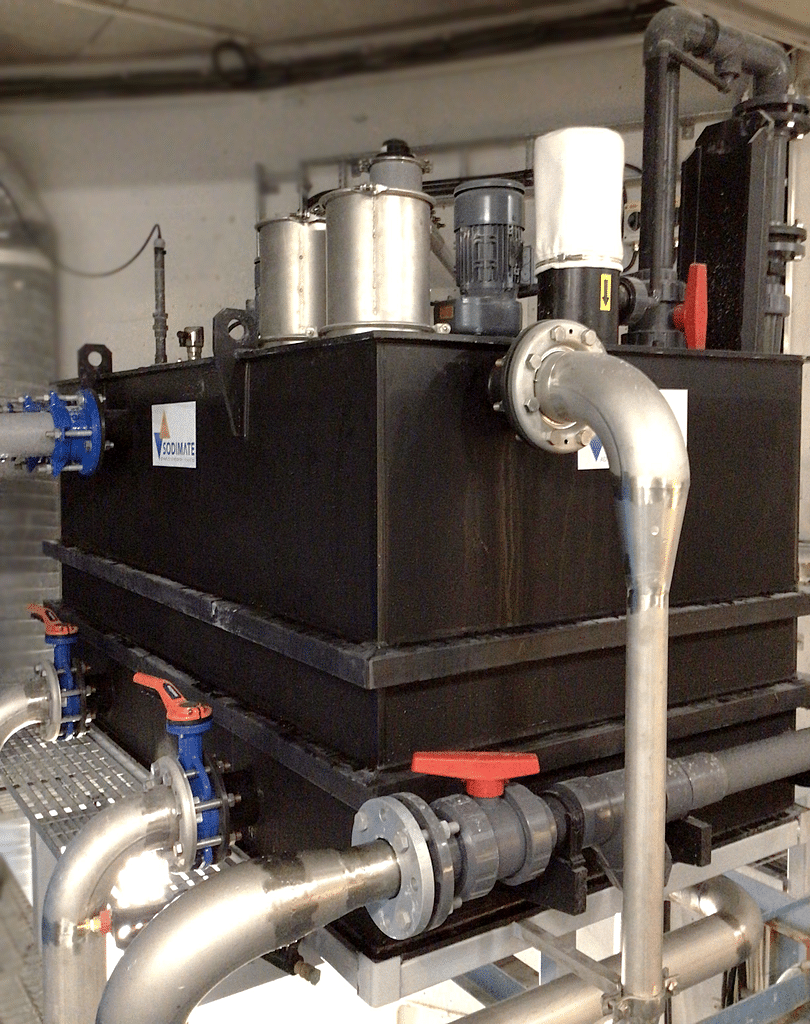

Sodimate’s system is based on an mechanical discharger that has previously been granted a patent, it indicates that it is a technically insightful solution that is unique in the market. The system, which is the result of long-term development work, is still one of the best options available for limescale treatment, and its functionality has been verified in several locations.

Installation without interruptions – Hyxo and Terco solved the challenges

Upgrades at water utilities are challenging, as the water supply cannot be interrupted. That is why it was critical to install the new equipment alongside the old one and to deploy it smoothly.

Hyxo supplied the equipment and Terco was responsible for the installation.

“In projects like this, it is a great advantage that in addition to the equipment procurement, the design, installation and commissioning are also carried out through the same operator. It makes it much easier for the customer, as they don’t have to worry about coordinating different operators,” says Pesu, the end customer.

Other plant development work was also carried out in connection with the project, which enabled a more cost-effective implementation.

Improved operational reliability, easier access to spare parts

After the commissioning of the new equipment, Kymen Vesi’s experiences have been positive. “Operational reliability has clearly improved. The availability of spare parts and the speed of maintenance have also improved,” Pesu says.

The Sodimate equipment is designed to be user-friendly and requires less maintenance. “When the equipment works without constant problems, you save both time and money,” Saari sums up.

Conclusion: Easy and reliable dosing system

The new limescale alkalization system has shown that limescale can be easy and reliable to use – as long as the equipment is right. Kymen Vesi’s experience shows that old bad experiences with lime can be forgotten, and modern technology can achieve both financial and operational benefits.

“If another water utility has had problems with lime supply in the past, I recommend that you familiarise yourself with Sodimate’s modern solutions. With the right equipment, the use of limescale is a sensible and cost-effective choice,” Hyxon Rusi sums up.