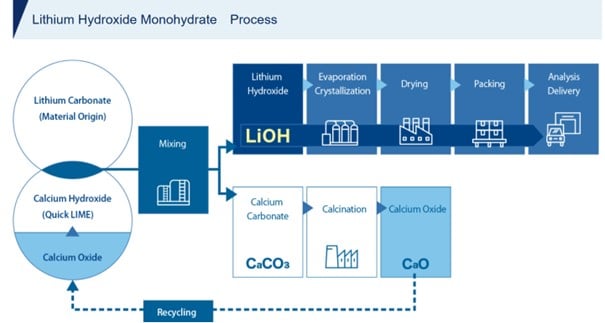

Sodimate has played a key role in a major project for battery manufacturing in Japan. Our expertise facilitated participation in the production of lithium hydroxide monohydrate, a critical step in the supply chain of lithium-ion batteries, which are indispensable for electric vehicles and various technological applications.

This initiative aims to reduce Japan’s dependency on imports, particularly from China, while strengthening the national battery supply chain. The Japanese government actively supports such projects to foster innovation and enhance domestic production capabilities.

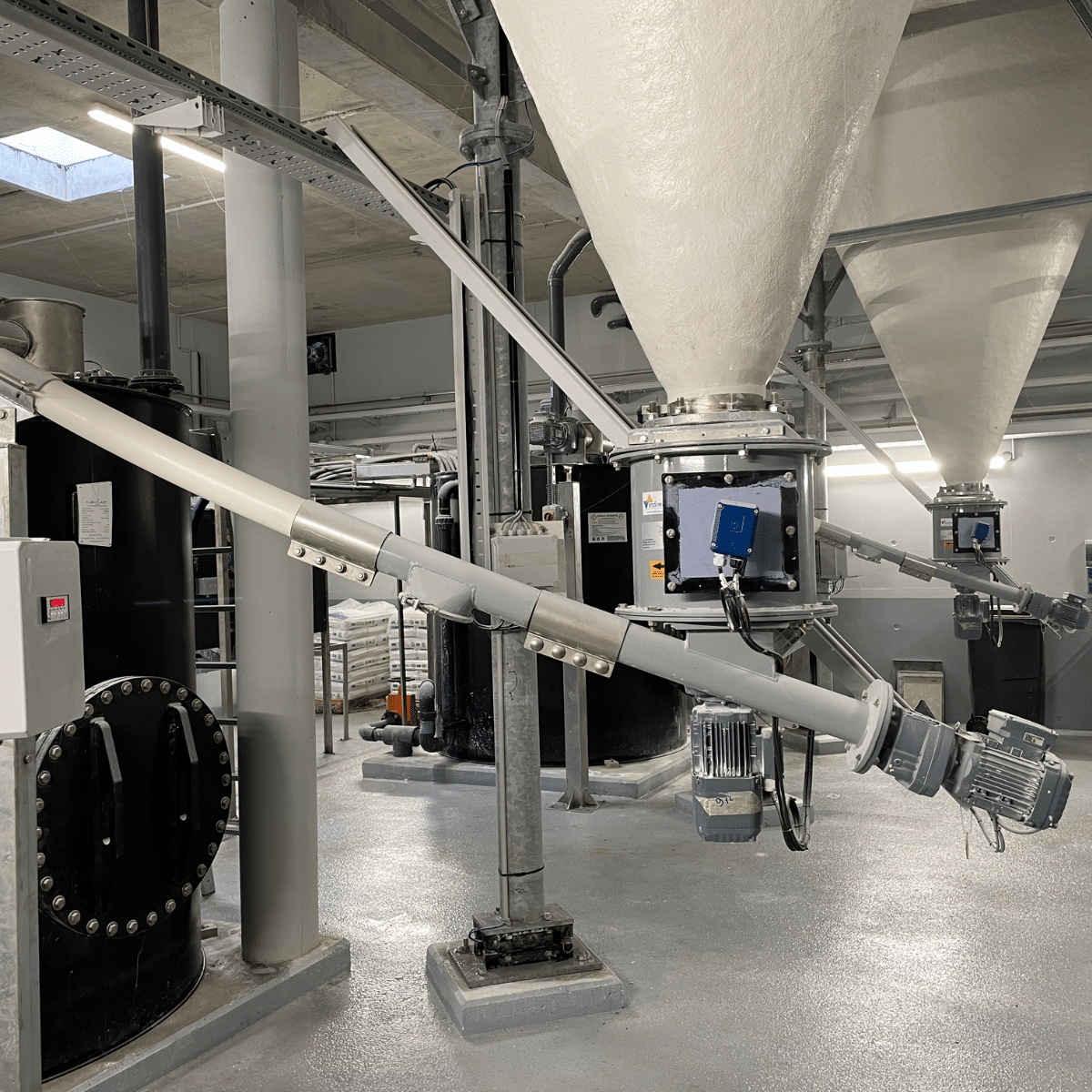

The comprehensive project includes the following installations:

1. Complete quicklime slaking system:

- A discharge and metering system under a 60m³ silo, ensuring efficient material flow.

- A dosing unit and conveyor for precise material handling.

- A 12 m³ slaking tank, mounted on load cells for precise control and measurement.

- A 20 m³ lime milk storage tank, designed for optimal containment and processing.

2. Installation for discharge and conveying of recycled quicklime:

- A 25 m³ recycled lime silo, ensuring seamless integration with the slaking process.

- An advanced feeding system to supply the slaking tank effectively.

3. Lithium carbonate preparation system:

- A discharge unit, enabling smooth material flow.

- A dosing system for accurate preparation.

- A 10 m³ lithium carbonate preparation tank, engineered to dose and prepare this essential component for the production of lithium hydroxide monohydrate (LiOH·H₂O).

Results:

Our integrated and efficient system enables optimized production of lithium hydroxide monohydrate, a critical material for the battery industry, meeting the growing demands driven by the energy transition.

We are delighted to provide innovative and sustainable solutions to support our partners in their strategic projects.