To meet increasingly stringent standards in water quality and micropollutant treatment, Saint-Brieuc Armor Agglomération has inaugurated a new drinking water production unit at Croix-Cholin in Ploufragan. The plant was designed and built by STEREAU.

Supplied by the Gouët dam in Saint-Barthélemy, this facility ensures high-standard drinking water production for over 150,000 residents in the Côtes-d’Armor region.

Key figures:

- Nominal flow rate: 1,850 m³/h, i.e. 37,000 m³/day

- Average production: 25,000 m³/day

Sodimate was selected to supply strategic equipment for two critical treatment stages:

Water remineralisation

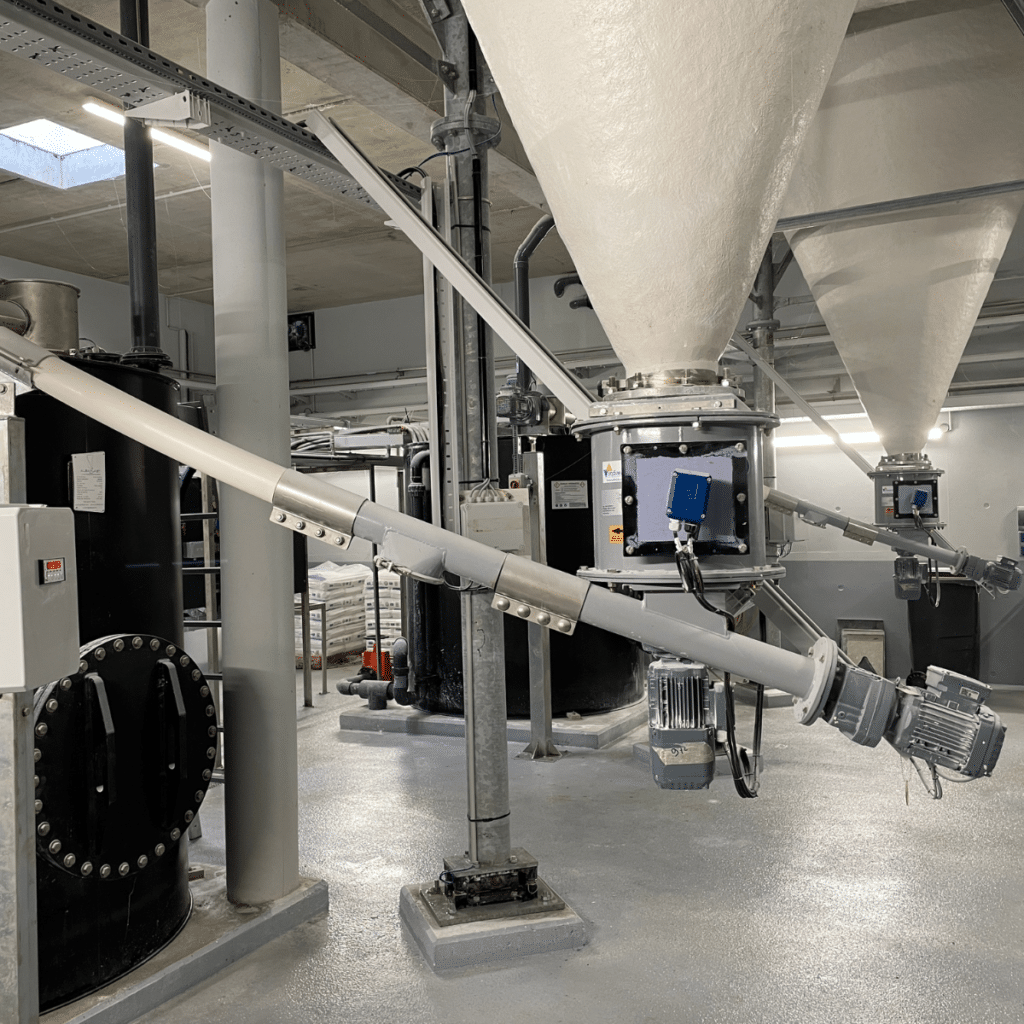

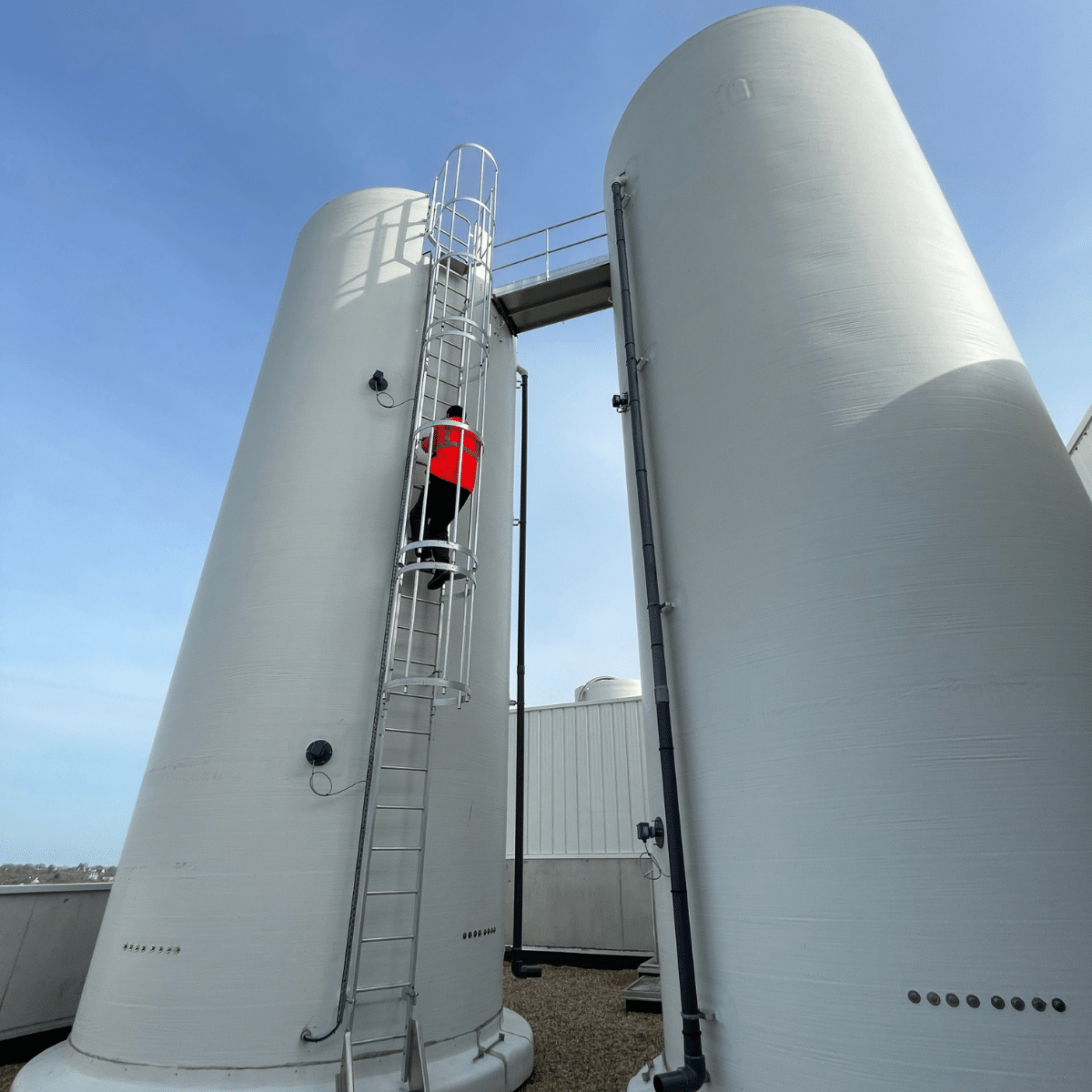

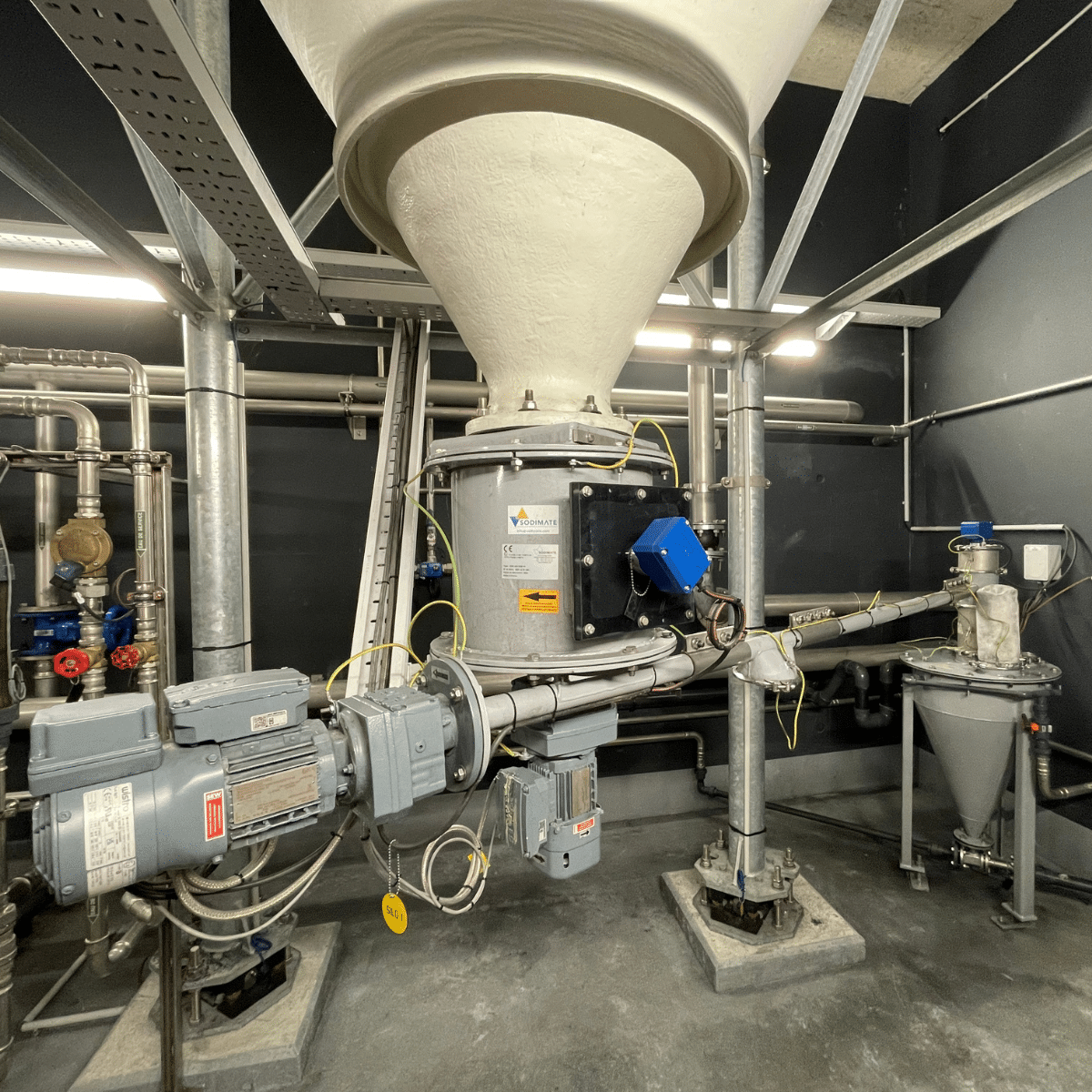

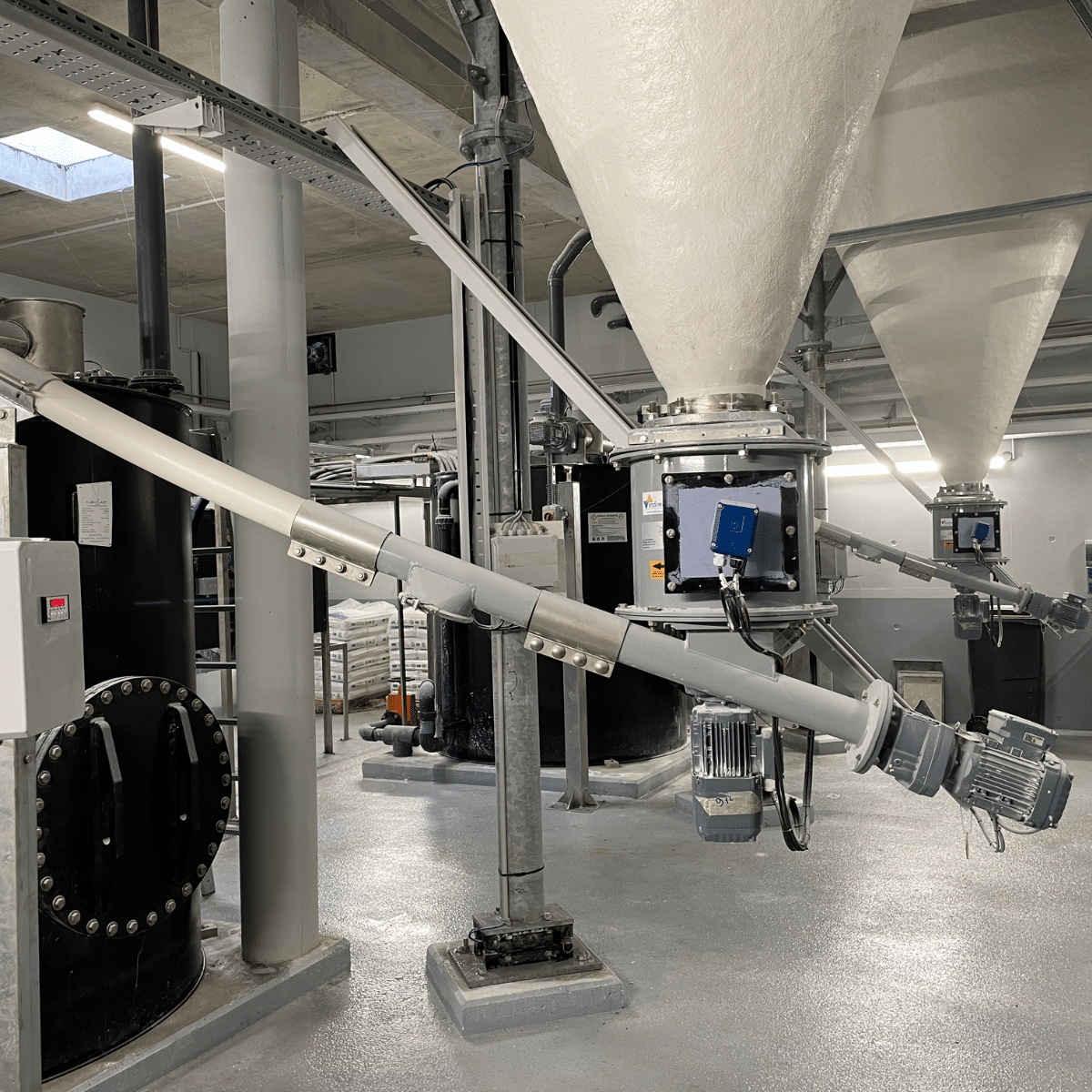

Sodimate installed, beneath two 80 m³ hydrated lime silos, a system composed of two ZDM dischargers combined with two DDMR screw feeders, ensuring accurate, controlled, and continuous lime dosing. This lime is used to adjust pH and remineralise the treated water.

Advantages of the Sodimate silo discharger:

- Even powder flow management

The discharger extracts powder horizontally across the entire cone surface using a rotating paddle turbine.

→ Prevents arching or clogging.

- No vibration = no compaction

Unlike bin activator system, the system transmits no vibration to the powder.

→ Avoids product recompaction in the silo, which would reduce flowability.

- Compact all-in-one system

Extraction and dosing mechanisms are integrated and mechanically synchronised (the screw feeder rotates simultaneously with the discharger).

→ Precise dosing + continuous flow = full process control.

- Quieter and more robust

No vibrating components = less noise, reduced mechanical stress, and improved durability.

- Proven performance with lime

Specifically designed for complex powders like hydrated lime, with thousands of successful installations in France and internationally.

Treatment of pesticides and total organic carbon (TOC)

Advantages of the hydroejector compared to traditional PAC preparation tanks:

- Simplified implementation

No need for a preparation tank or continuous agitation, significantly reducing the number of components.

→ Less maintenance and a smaller footprint, ideal for constrained spaces.

- Instant, in-line dosing

The PAC is dosed and directly injected into the water network via the hydroejector’s water jet, eliminating the risk of sedimentation or clogging in a preparation tank.

- No moving mechanical parts in the hydraulic circuit

The absence of a pump ensures greater system reliability and significantly lowers maintenance requirements.

- Safety and hygiene

The closed, compact system limits chemical handling and generates significantly less dust compared to traditional systems with open tanks.

- Lower investment and operating costs

The proposed solution requires fewer installations (no tank, agitator, or dedicated dosing pump), leading to reduced energy consumption and enhanced energy efficiency.

These precise and proven solutions are designed to guarantee optimal reagent injection while meeting the highest standards of health safety and environmental performance.