Home » Injector screw type ID

The purpose of the injector ID is to introduce Quick or Hydrated Lime into the MBV sludge mixer or a preparation tank at a stable rate. The injector ID is located between the metering conveyor outlet and the discharge equipment. In order to optimize operation time, the injector can be operated even when moisture is present. The injector replaces the isolation valve, which is necessary in humid conditions.

The injector is installed at a horizontal position, which suppresses the product’s gravitational flow inside the conduit, preventing blockages during operation. There are various types and sizes of injector screws, and the ideal injector screw is dependent upon the desired discharge rate.

Construction: Stainless steel metal work and carbon steel spiral screw.

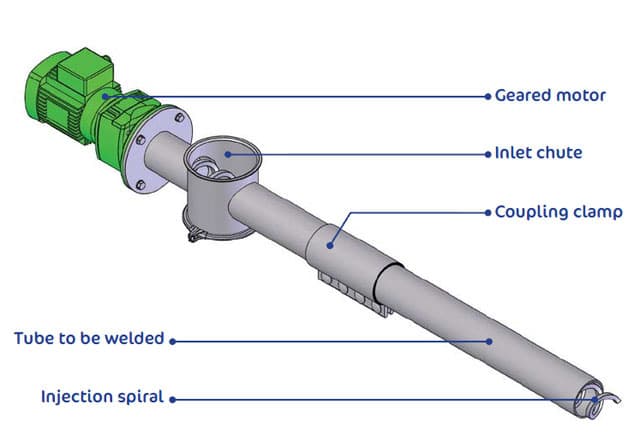

The injector screw system consists of an inlet chute, which receives the product that is being dosed, and a spiral screw, which transfers it to the injection point. The motor power and the spiral section are oversized to reduce the force created by the moisture.

During operation of the injector ID, moisture and steam are caught by product buckling created by the spiral screw. The spiral screw is self-cleaning and should automatically remove any hardened material that builds up during operation.

When the system stops, the injector runs until it has is completely discharged the product, due to a timer. The injector spiral will crush and eject any material residue solidification as soon as the system commences operation.

Advantages