A pneumatic conveying system is a core piece of a bulk material handling system. This system uses compressed air (or any other gas) to achieve great performance with difficult materials. It transfers powders, granules, and other dry bulk materials through an enclosed pipeline from one process area to another. The flow rate ranges from 0.5 lb/h to 2,200 lb/h.

At the beginning of the process, the air motor pushes air through the system, and it operates under pressure. At the end of the process, the air motor pulls air through the system and then runs under a vacuum. By controlling the pressure or vacuum and airflow within the system, we ensure the safety of materials in the transfer.

There are many advantages to using pneumatic conveying systems. One of the most important is the ability to reduce product breakage. Pneumatic conveying systems may need to be adjusted to get the best results for product breakage. But there are ways to preserve as much product as possible.

Few Important Explanations Regarding How Pneumatic Conveying Systems Can Avoid Product Breakage:

Speed

The faster the blowing device runs, the more likely it is that products will break. Many organizations need to achieve a “sweet spot” between productivity and breakage. Pneumatic conveying systems can be tailored to individual processes. You can set it at virtually any speed, to ensure that the system is flowing effectively, and the product isn’t being damaged. For the best results, companies test out multiple variations to determine optimum speed.

Because of the way the pneumatic system works, it may require some adjustments to correct the speed of the pneumatic tubes. Also, the system must repeatedly check the speed of the tubes to ensure that the speed is not too high. The more metrics tracked by the pneumatic conveying system, the easier it is to control and improve the system.

Pipe Size Diameter

The pipe diameter in the pneumatic conveying system controls, the speed at which the products pass through the conveying system to the amount of breakage. If the pipe size is too small, it will incur a high-pressure drop. Specialists can help in determining whether the pipe size diameter of conveying system is sufficient or whether they need to adjust the pipe size.

Hybrid Conveying

Hybrid conveying is a unique and inventive combination of pneumatic and mechanical conveying. It is a low-velocity vacuum conveying, which is neither a dense phase nor a dilute phase. It gives industries the option of building a custom conveying device that can reduce damage and improve accuracy. When suitable, it can be moved mechanically, and when more speed and accuracy are required, it can move pneumatically. Ensuring, that the company can achieve both goals.

Many factories use a hybrid conveying system to deliver their product. Though it can be rigorous to align a well-integrated system.

System Design

If a pneumatic system is still leading to product breakage, it’s advantageous to have a professional design team make adjustments. System designers can isolate problem areas by inspecting each component of the process. By consulting a professional designer and redesigning the system, the organization can save product, time, and money.

Monitoring Process

While damage may become evident through the pneumatic conveying process, precise monitoring is required. Engineers must monitor the entire process and isolate any issues that could be causing damage.

It’s possible that product can also be damaged during the pneumatic conveying phase. However, it is not accurately recognized or tested until the product has moved to quality assurance.

Some elements of product breakdown will always be part of any conveying system. But pneumatic has several advantages over other processes.

First, it can be completely customized, including the pipe’s size, diameter, speed, and vibration. Second, it is a precise and efficient method of moving and sorting products, with several improvements that can enhance the system more.

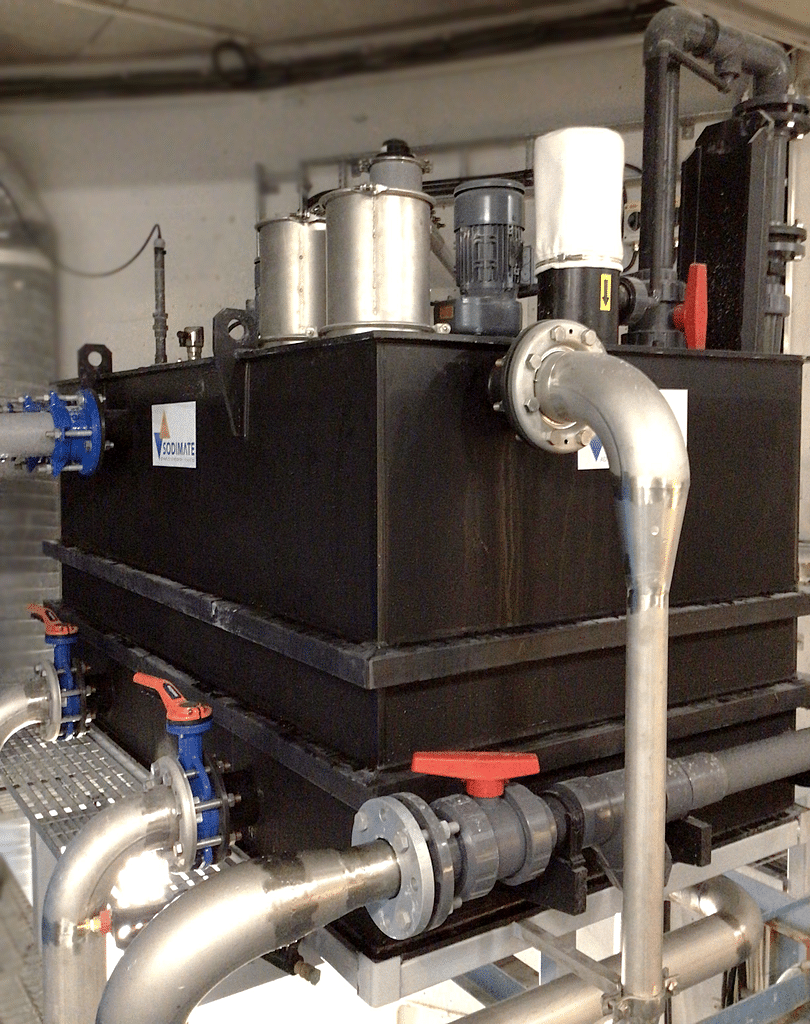

Are you facing product breakage? Or other issues with the existing pneumatic conveying system? Choose the correct pneumatic conveying system with Sodimate, Here, we have a team of experts with experience shaping ingredient automation. Feel free to contact us! Our team will help you make plants and processes run smoother.