Home » Addition of lime on the waste rock from aggregate quarries

SODIMATE, with over 30 years of experience, SODIMATE supplies turnkey solutions for the storage and the liming of quarry waste rock. This process improves the profitability of aggregate quarries. SODIMATE supplies storage silos, discharging and lime metering systems. We carry out two types of metering equipment for lime, either volumetric or by weight loss.

To be able to discharge and meter the lime powder from a cylindrical-conical storage silo, SODIMATE has designed and patented a fully mechanical flow device called “ARCH BREAKER” (also Mechanical bin activator) that integrates underneath a volumetric metering screw system.

Regardless of the silo capacity (ranging from 1 to > 100 m3), the Mechanical arch breaker ZDM 400 combined with its metering screw DDM ensures a total flow control and an accurate metering of your lime powder.

The dry reagent is kept at a constant level in the Arch Breaker’s hopper, which ensures high metering accuracy regardless of the quantity of powder remaining in the silo. This set provides unmatched performance for a volumetric metering screw positioned right under a silo with lime flow rates ranging from less than 1 kg / h to almost 12 T / h – regarding the screw. Why install a waste rock liming process in a quarry?

The so-called “waste” clay material can represent up to 30 % of the annual production of a quarry. These unusable rocks were disposed of in the past, which represented a net loss for the production site. The addition of lime facilitates the segregation from the particle size of the materials to be treated. The aim for quarries is to improve their profitability and the longevity of the site. With the addition of lime, the rate of unused materials extracted can potentially drop from 30% to 10%.

As the waste rock is reprocessed, it is no longer necessary to store it, thus saving space!

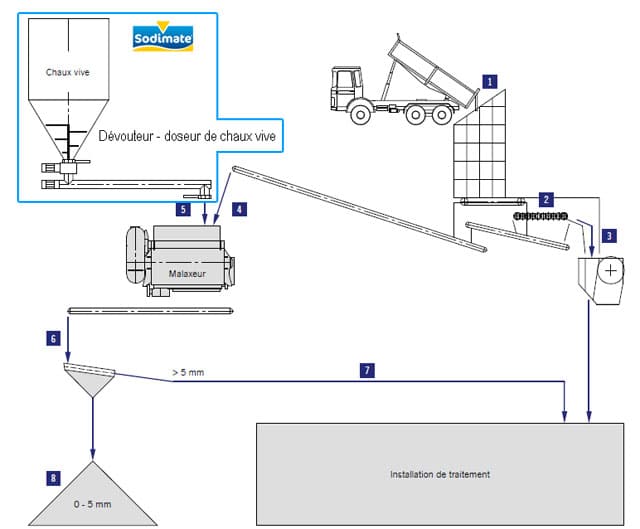

Process steps:

Process diagram: (quicklime – Arch breaker – metering screw feeder – mixer – treatment plant)

Waste rock at the mixer inlet:

Materials supplied 0 - 40 mm, sticky, with clay, considered as waste

Crushed rocks at the mixer outlet:

Screened materials > 5 mm

Product valuable as fertilizer:

Screenable clay materials < 5 mm with quicklime

Materials in a BHS SONTHOFEN mixer

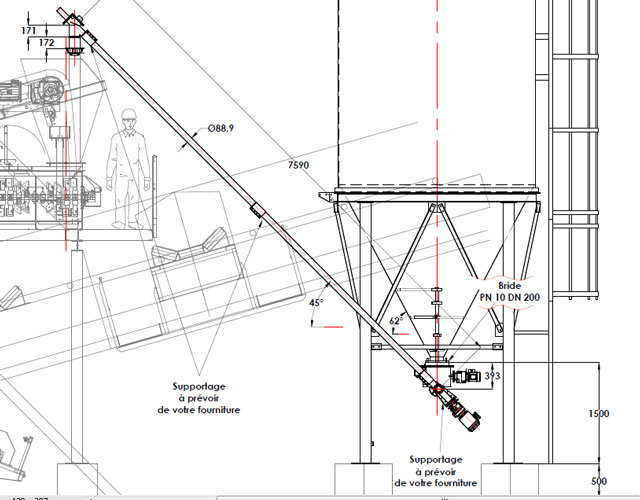

Example of a quarry waste rock liming installation

Control panel to regulate lime according to the weight of the waste rock in the mixer or on the belt conveyor

We have also developed a control panel for our lime metering system. The belt conveyor is on load cells for this type of installation. The weight of the waste rock on the belt conveyor increases or decreases the amount of lime injected in accordance with the liming rate set by the operator (usually between 1 and 5% of the weight of materials on the conveyor belt).

Companies who have trusted us with our products: Colas, Eurovia, Blanloeil, etc…