Life can’t be imagined without water, and that’s why it’s important to use it efficiently and conserve it whenever possible. In many places, wastewater is treated to give out clean water. One of the methods is using activated carbon for wastewater treatment, which works by adsorption. This is a process by which molecules, atoms, or ions adhere to the surface of the activated carbon particles. Sodimate offers a variety of ready solutions for wastewater treatment with equipment that has activated carbon in it to ensure a clean and filtered output. To learn about another way of wastewater treatment, click on the link.

What Are the Two Main Methods of Activation?

There are two main methods by which carbon can be activated before use, and they are chemical activation and thermal or steam activation. The base material is anything that has a high content of carbon in it, including coconut husks and shells, wood, bamboo, willow peat, coal, macadamia nut shells, lignite, and others. Depending on the method of activation to be used, some base materials are better suited than others.

Chemical Activation

In the chemical activation of carbon, the most common chemicals used are zinc chloride, phosphoric acid, and potassium hydroxide. These have been found to create activated carbon with the highest porosity levels. As the efficiency of activated carbon increases with an increase in porosity, it’s important to keep it high. This is also the method of choice for activation when the starting material being used is peat or wood.

The chosen material is first milled or crushed to achieve the desired size of particles and then mixed with the concentrated solution of the dehydrating compound to be used. After this, it is dried and heat-treated in an inert atmosphere between 400°C and 700°C. It is finally washed with water to remove the activating agent, then separated from the slurry, dried off, and prepared for use depending on the application.

Steam Activation

In steam activation of carbon, the base material is first burnt to a char and then put in a furnace that heats it to temperatures between 927°C and 980°C with steam in the absence of oxygen. Volatile compounds are all removed at this stage and the layers of carbon are peeled off to expose enlarged internal pores on a carbon skeleton. After the activated carbon has cooled, it’s either washed with water or acid to remove the ash content. If acid is used, the resulting carbon is thoroughly rinsed with water.

How is activated carbon used in water treatment?

Both industrial and municipal wastewater can be treated to remove impurities and make it potable, creating clean water for a number of different applications. In this process, activated carbon is usually used in the final stages after processes like sedimentation and flocculation.

After all the suspensions have been removed, the water is often passed through a few filters made of activated carbon. This is necessary to ensure that a maximum load is achieved in each filter, and impurities that fail to be adsorbed previously, can be adsorbed in the next one and so on.

The resulting clean water can be used for drinking or as service water in swimming pools and aquariums, to name a few. The intended use of the treated water dictates the activated carbon filtration system that will be used.

Chlorine Removal

Chlorine is used widely in the disinfection of public water supplies as it is a powerful germicide. In larger quantities, however, it can cause problems when consumed and leave the water with an undesirable taste. This is where activated charcoal comes in, as it’s very effective in the removal of chlorine from water. Granular activated carbon is the type of carbon that’s most commonly used in big water treatment filters. Flow rates of between 2 to 3 GPM/ft3 are employed because the residence time spent in contact with the carbon is directly proportionate to the amount of chorine removed.

Removal of Organic Matter

The quality of activated carbon that is used in the removal of organic matter from wastewater is its particulate nature. Organic matter includes decaying plant life and manmade sources, and it gets trapped inside the activated carbon filter in the process of adsorption. Carbon with small pores makes the most effective filter as it does not allow any of the contaminants to pass through. Depending on the water purification needs, the activated carbon filter can be made from a material that can interact chemically with the organic matter in the water.

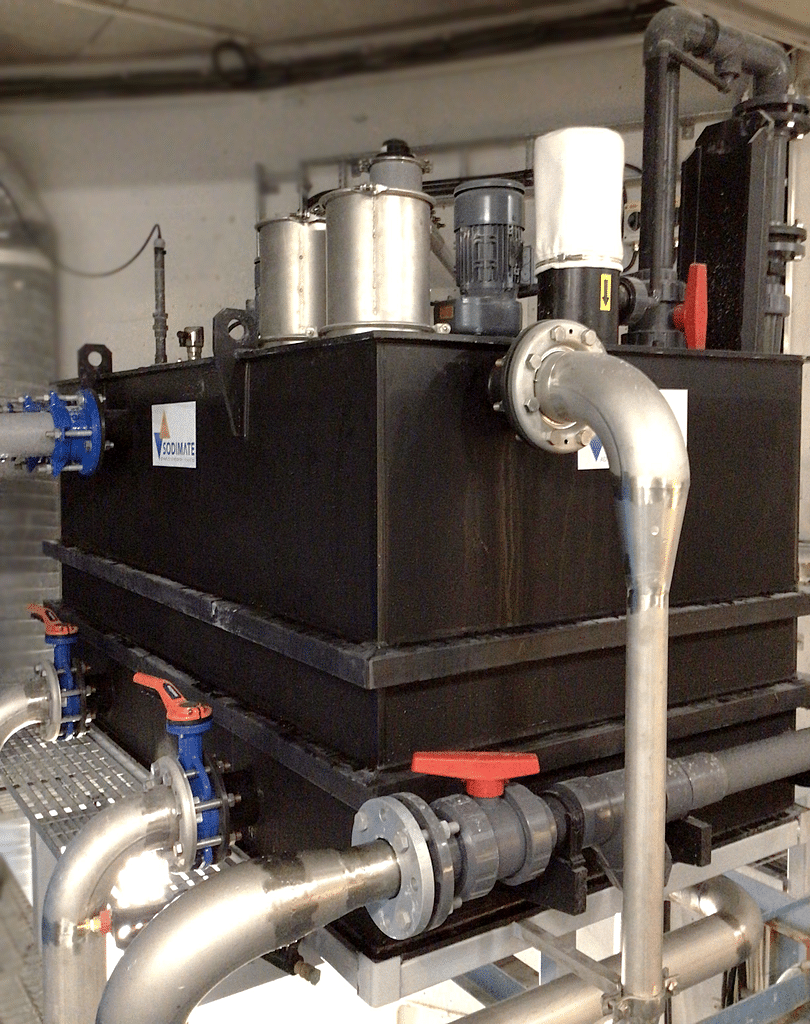

Equipment by Sodimate

The experts at Sodimate are ready to provide you with conclusive advice on the right system and equipment for activated carbon. Sodimate worldwide leader in bulk handling and processing equipment for water treatment and supply of activated carbon equipment for wastewater treatment such as:

- Silo

- Arch Breaker

- Metering Conveyor

- Activated Carbon Preparation Tank

- Skid of Pump

- Hydro ejector, which replaces the preparation tank with the skid of the pump.

Activated carbon is a non-expensive but effective solution for the treatment of wastewater. If you’re on the market for filters and other equipment for treating water, Sodimate is your ready and capable partner. At Sodimate, you will be presented with a variety of options and advice on the most effective solution.